We keep on with the basic principle of “quality to start with, support very first, continuous improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for Top Suppliers China Cutting 1000W High Speed Metal Fiber Laser Cutting Machine, Adhering to the business philosophy of ‘customer first, forge ahead’, we sincerely welcome clients from at home and abroad to cooperate with us.

We keep on with the basic principle of “quality to start with, support very first, continuous improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for China Metal Fiber Cutting, Cutting Machine, We put the product quality and customer’s benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, let us work together to get success.

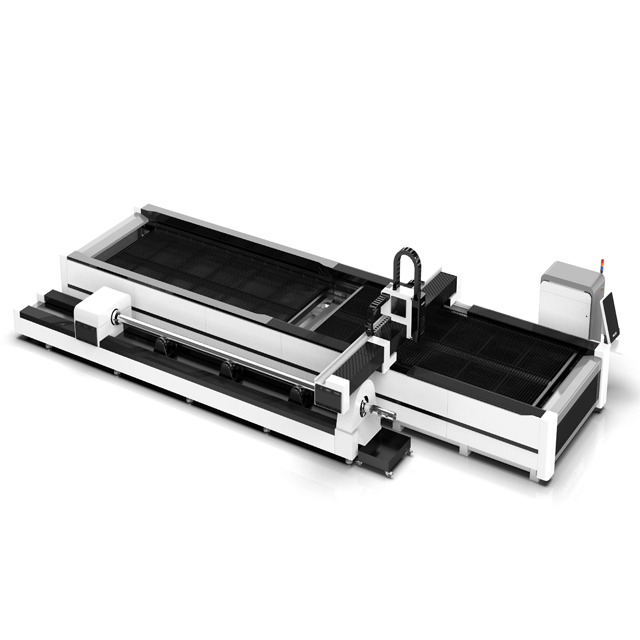

Main Features of KF-T Series dual used fiber laser cutter:

1. BETTER CUTTING QUALITY

Laser has a narrower kerf, meaning less material is wasted. More than this, laser cutting requires less manpower and even no secondary processing for most parts.

2.HIGHER CUTTING PRECISION

Laser cutting, 0.14mm; Plasma cutting, 0.4mm And at the vertical cross, laser cutting has a smaller bevel angle than plasma cutting.

3. LOWER CUTTING COSTS

Getting rid of secondary finishing, with smoother cutting surface, less dross, and smaller deformation.

4. FASTER CUTTING SPEED

Laser cutting speed can reach up to three times faster than plasma cutting.

5. ENVIRONMENT-FRIENDLY PROCESSING

Fiber laser cutting machine is cleaner and more environment-friendly than the smoky and noisy plasma cutting.

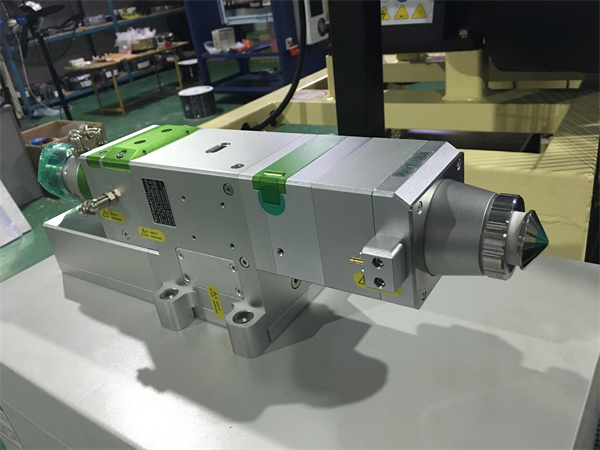

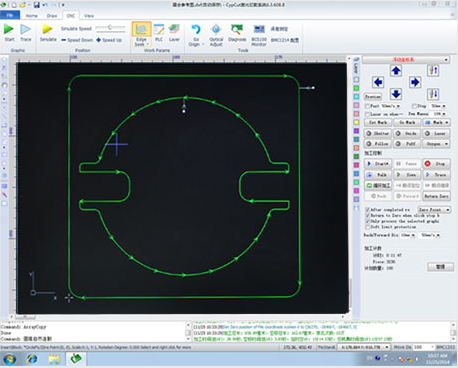

Configuration :

Techinical Parameters

|

Model |

KF-TSeries |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Tube Cutting Length |

3m / 6m |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W /6000W /8000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting Parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

||

|

16 |

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|||

|

18 |

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|||

|

20 |

0.5–0.8 |

0.5–0.8 |

||||

|

22 |

0.3–0.7 |

0.4–0.8 |

||||

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

||

|

8 |

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|||

|

10 |

0.6–0.8 |

0.8–1.2 |

||||

|

12 |

0.4–0.6 |

0.5–0.8 |

||||

|

14 |

0.4–0.6 |

|||||

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

||

|

5 |

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

||

|

6 |

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|||

|

8 |

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|||

|

10 |

0.4–0.7 |

0.6–1.2 |

||||

|

12 |

0.3-0.45 |

0.4–0.6 |

||||

|

16 |

0.3–0.4 |

|||||

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

||

|

5 |

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

||

|

6 |

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|||

|

8 |

0.5–0.7 |

0.7–1.2 |

||||

|

10 |

0.2–0.5 |

|||||

video

We keep on with the basic principle of “quality to start with, support very first, continuous improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for Top Suppliers China Cutting 1000W High Speed Metal Fiber Laser Cutting Machine, Adhering to the business philosophy of ‘customer first, forge ahead’, we sincerely welcome clients from at home and abroad to cooperate with us.

Top Suppliers China Metal Fiber Cutting, Cutting Machine, We put the product quality and customer’s benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, let us work together to get success.

-

Factory made hot-sale Faith China Manufacturer ...

-

Wholesale China Top Grade Automatic CNC Metal L...

-

Professional Factory for China 2020 New Raycus ...

-

Wholesale Dealers of China 1035 High Precision ...

-

Professional Factory for China Metal Pipe Cutti...

-

Quoted price for China Factory 1kw-6kw 3015 Met...