We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Super Lowest Price China Even Hardness Forged Grinding Media Alloy Iron Rod for Mining, We give priority to quality and customer pleasure and for this we follow stringent excellent control measures. We’ve got in-house testing facilities where our items are tested on every single aspect at different processing stages. Owning to latest technologies, we facilitate our clients with custom made creation facility.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for China Steel Grinding Rod, Steel Iron Bar, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

Video

Application

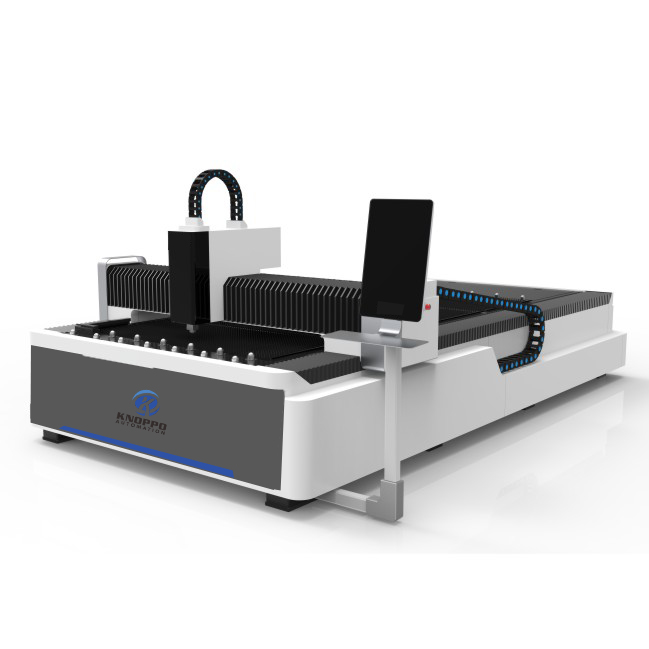

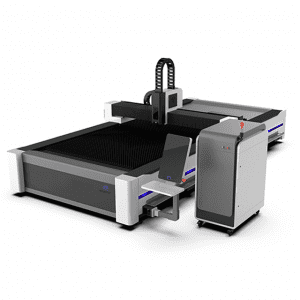

Applicable Materials Of Fiber Laser Cutter

Cutting stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheet, metal plate etc.

Applicable Industries Of Fiber Laser Cutter

Machinery parts, electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts and other metal cutting fields.

Sample

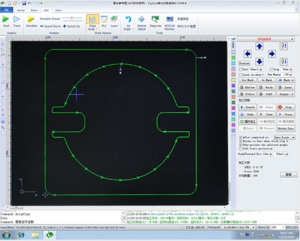

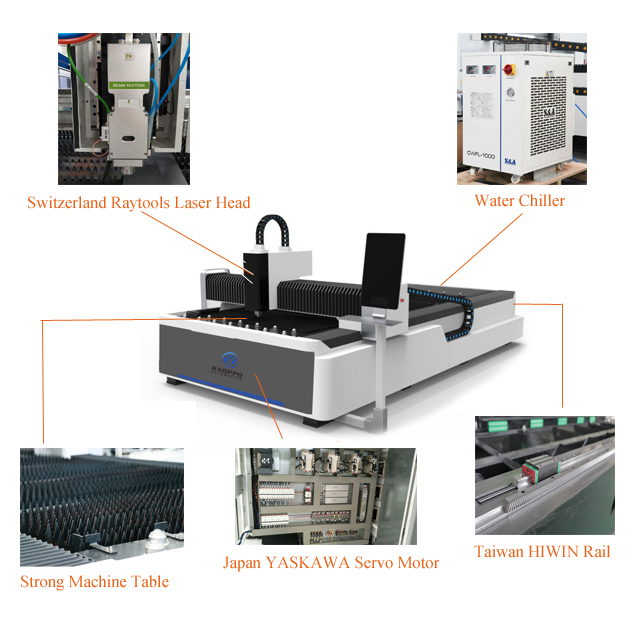

Configuration

Techinical Parameters

|

Model |

KF Series |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*1500mm / 6000*2000mm/ 6000*2500mm |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W /6000W / 8000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting Parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

|

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

|

|

16 |

|

|

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|

|

18 |

|

|

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|

|

20 |

|

|

|

0.5–0.8 |

0.5–0.8 |

|

|

22 |

|

|

|

0.3–0.7 |

0.4–0.8 |

|

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

|

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

|

|

8 |

|

|

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|

|

10 |

|

|

|

0.6–0.8 |

0.8–1.2 |

|

|

12 |

|

|

|

0.4–0.6 |

0.5–0.8 |

|

|

14 |

|

|

|

|

0.4–0.6 |

|

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

|

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

|

|

5 |

|

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

|

|

6 |

|

|

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|

|

8 |

|

|

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|

|

10 |

|

|

|

0.4–0.7 |

0.6–1.2 |

|

|

12 |

|

|

|

0.3-0.45 |

0.4–0.6 |

|

|

16 |

|

|

|

|

0.3–0.4 |

|

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

|

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

|

|

5 |

|

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

|

|

6 |

|

|

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|

|

8 |

|

|

|

0.5–0.7 |

0.7–1.2 |

|

|

10 |

|

|

|

|

0.2–0.5 |

|

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Super Lowest Price China Even Hardness Forged Grinding Media Alloy Iron Rod for Mining, We give priority to quality and customer pleasure and for this we follow stringent excellent control measures. We’ve got in-house testing facilities where our items are tested on every single aspect at different processing stages. Owning to latest technologies, we facilitate our clients with custom made creation facility.

Super Lowest Price China Steel Grinding Rod, Steel Iron Bar, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

-

Factory Cheap Hot China Top Selling Good Qualit...

-

High quality China Factory Fiber Laser Cutting ...

-

Factory directly China 5′ X 10′ High Power Thic...

-

Bottom price China 3mm Stainless Steel Aluminum...

-

Hot Sale for China CNC 500W Fiber Metal Laser C...

-

OEM/ODM Supplier China New Design Fiber 1000W L...