The company upholds the philosophy of “Be No.1 in quality, be rooted on credit and trustworthiness for growth”, will continue to serve old and new customers from home and overseas whole-heatedly for Special Design for China 1325 3015 2040 1kw 2kw 3kw 4kw 5kw 6kw 8kw CNC Sheet Metal Fiber Laser Cutting Machine Factory Price, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, and the right product.

The company upholds the philosophy of “Be No.1 in quality, be rooted on credit and trustworthiness for growth”, will continue to serve old and new customers from home and overseas whole-heatedly for china fiber laser cutting machine, Metal Cut, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we offer, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and comprehensive parameters and any other info weil be sent for you timely for the inquiries. So remember to get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We’re confident that we’re likely to share mutual results and build solid co-operation relations with our companions in this market. We’re looking forward to your inquiries.

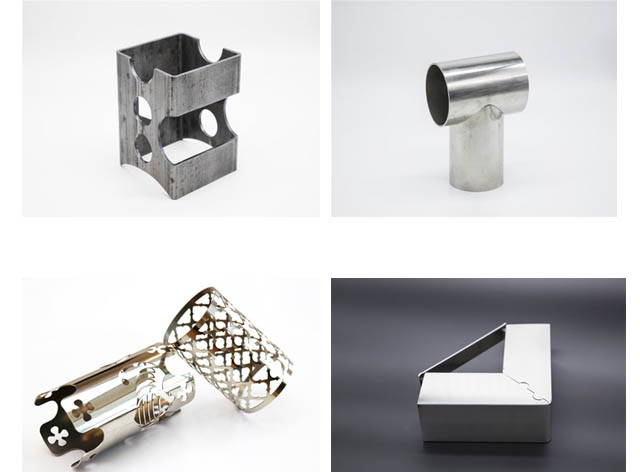

Application

Applicable Materials Of Fiber Laser Tube Cutting Machine

KT6 fiber laser tube cutting stainless steel tube, carbon steel tube, mild steel tube, galvanized steel tube, iron tube, inox tube, aluminium tube, brass tube and other metal tube, metal pipe. Shape can be round tube, square tube, rectangular tube and angle steel etc.

Applicable Industries Of Fiber Laser Tube Cutting Machine

Machinery parts, electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts, furniture and other metal cutting fields.

Sample

Configuration

Automatic Electric Chuck

Automatic electric chuck, claw DC motor drive. The clamping motor current is sensitive, adjustable and stable. The clamping range is wider and clamping force is larger. Non – destructive pipe clamping, fast automatic centering and clamping pipe, performance is more stable. The chuck size is smaller, rotation inertia is low, and dynamic performance is strong. Self-centering electric chuck, gear transmission mode, higher transmission efficiency, long working life and high work reliability.

Chuck Intelligent CNC Self-centering, Precise Control of Clamping Position

The chuck intelligent CNC self-centering high precision position and torque control can freely switch tube of different thickness, prevents pinch error and deformation of thin tube holding.

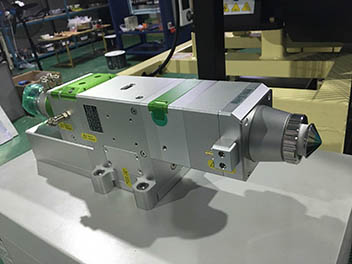

Switzerland Raytools Laser Head

Applicable to various focal lengths, which are controlled by machine tool control system. Increasing perforation focus length, separately setting perforation focal length and cutting focal length, improve cutting accuracy. NO.1 Brand in the world.

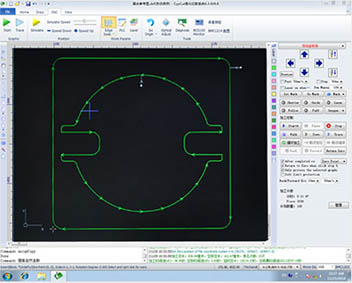

CYPCUT Control System

CYPCUT Control system of fiber laser tube cutting machine can realize intelligent layout of graphics cutting and support the import of multiple graphics, optimizing cutting orders automatically, searching edges smartly and automatic positioning. Control system adopts the best logic programming and software interaction, provides stunning operation experience, effectively enhancing the utilization of sheet metal and reducing waste. Simple and fast operation system, efficient and accurate cutting instructions, effectively improve the user experience.

Water Chiller

Control the temperature of laser head and laser source automatically.

Techinical parameters

|

Model |

KT6 |

|

Wavelength |

1070nm |

|

Max Cutting Diameter |

350mm |

|

Tube Cutting Length |

6m / 9m / 12m |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

|

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

|

|

16 |

|

|

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|

|

18 |

|

|

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|

|

20 |

|

|

|

0.5–0.8 |

0.5–0.8 |

|

|

22 |

|

|

|

0.3–0.7 |

0.4–0.8 |

|

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

|

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

|

|

8 |

|

|

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|

|

10 |

|

|

|

0.6–0.8 |

0.8–1.2 |

|

|

12 |

|

|

|

0.4–0.6 |

0.5–0.8 |

|

|

14 |

|

|

|

|

0.4–0.6 |

|

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

|

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

|

|

5 |

|

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

|

|

6 |

|

|

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|

|

8 |

|

|

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|

|

10 |

|

|

|

0.4–0.7 |

0.6–1.2 |

|

|

12 |

|

|

|

0.3-0.45 |

0.4–0.6 |

|

|

16 |

|

|

|

|

0.3–0.4 |

|

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

|

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

|

|

5 |

|

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

|

|

6 |

|

|

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|

|

8 |

|

|

|

0.5–0.7 |

0.7–1.2 |

|

|

10 |

|

|

|

|

0.2–0.5 |

|

Video

The company upholds the philosophy of “Be No.1 in quality, be rooted on credit and trustworthiness for growth”, will continue to serve old and new customers from home and overseas whole-heatedly for Special Design for China 1325 3015 2040 1kw 2kw 3kw 4kw 5kw 6kw 8kw CNC Sheet Metal Fiber Laser Cutting Machine Factory Price, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, and the right product.

Special Design for China Fiber Laser Cutting Machine, Metal Cut, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we offer, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and comprehensive parameters and any other info weil be sent for you timely for the inquiries. So remember to get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We’re confident that we’re likely to share mutual results and build solid co-operation relations with our companions in this market. We’re looking forward to your inquiries.

-

Competitive Price for China Tube Sheet Metal Mu...

-

OEM Factory for China CNC Flame Plasma Cutting ...

-

Hot sale China 110*110mm 200*200mm 300*300mm La...

-

High Quality China Multifunctional Deep Cutting...

-

Good quality China 1000W 1500W 2000W 3000W 4000...

-

8 Years Exporter Pipe Laser Cutting Machine Mad...