As for aggressive selling prices, we believe that you will be searching far and wide for anything that can beat us. We are able to state with absolute certainty that for such good quality at such costs we’ve been the lowest around for Short Lead Time for China Laser Pipe and Tube Cutting Machine Fiber Laser Pipe Cut CNC Laser Tube Cutting Machine, Our corporation is dedicated to giving customers with superior and secure excellent items at competitive rate, creating just about every customer content with our services and products.

As for aggressive selling prices, we believe that you will be searching far and wide for anything that can beat us. We are able to state with absolute certainty that for such good quality at such costs we’ve been the lowest around for China Tube Laser Cutting Machine, CNC Laser Cutting Machine, Our objects have national accreditation requirements for qualified, high quality products and solutions, affordable value, was welcomed by people today all over the world. Our goods will continue to enhance within the order and look forward to cooperation with you, Need to any of those goods be of interest to you, be sure to letus know. We’ve been gonna be content to offer you a quotation up on receipt of your detailed needs.

Video

Features

1. Excellent beam quality: smaller spot size, higher work efficiency and better processing quality;

2. Fast cutting speed: about twice the cutting speed of CO2 laser machine or plasma cutting machine ;

3. High performance : the stable performance was acquired through the application of world’s top fiber laser source which makes it possible to cut at any point with equal quality through fiber transmission.

4. High electrical conversion efficiency: fiber laser cutting machine has 3 times higher electro-optical conversion efficiency than CO2 laser cutting machine, saving energy and protecting environment.

5. Low maintenance cost: fiber transmission without using reflective lenses saves a lot of time in optical path adjustment and achieves maintenance-free results.

Techinical parameters

|

Model |

KF3015 , KF4020 , KF6015 , KF6020 ,KF6025 |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W / 6000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

|

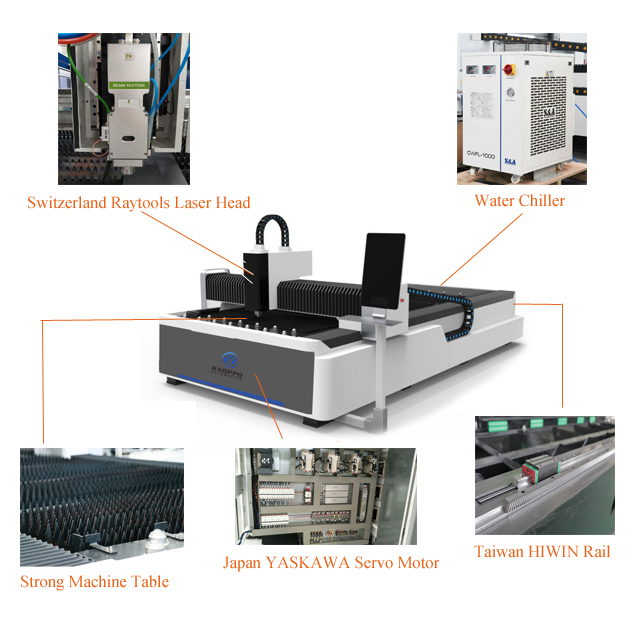

Laser Head |

Switzerland Raytools |

|

Laser Source |

Raycus / MAX / IPG |

|

System |

CYPCUT |

|

Servo Motor |

Japan Yaskawa |

|

Servo Driver |

Japan Yaskawa |

|

Water Chiller |

S&A |

Cutting parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

|

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

|

|

16 |

|

|

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|

|

18 |

|

|

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|

|

20 |

|

|

|

0.5–0.8 |

0.5–0.8 |

|

|

22 |

|

|

|

0.3–0.7 |

0.4–0.8 |

|

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

|

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

|

|

8 |

|

|

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|

|

10 |

|

|

|

0.6–0.8 |

0.8–1.2 |

|

|

12 |

|

|

|

0.4–0.6 |

0.5–0.8 |

|

|

14 |

|

|

|

|

0.4–0.6 |

|

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

|

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

|

|

5 |

|

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

|

|

6 |

|

|

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|

|

8 |

|

|

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|

|

10 |

|

|

|

0.4–0.7 |

0.6–1.2 |

|

|

12 |

|

|

|

0.3-0.45 |

0.4–0.6 |

|

|

16 |

|

|

|

|

0.3–0.4 |

|

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

|

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

|

|

5 |

|

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

|

|

6 |

|

|

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|

|

8 |

|

|

|

0.5–0.7 |

0.7–1.2 |

|

|

10 |

|

|

|

|

0.2–0.5 |

|

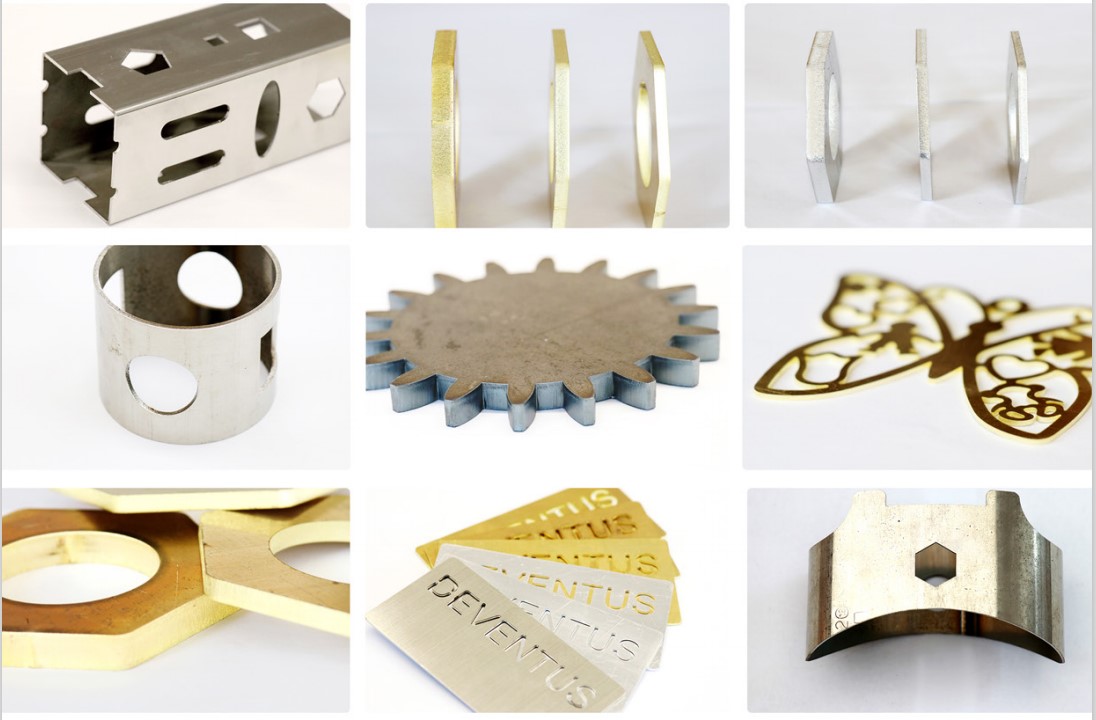

Sample

As for aggressive selling prices, we believe that you will be searching far and wide for anything that can beat us. We are able to state with absolute certainty that for such good quality at such costs we’ve been the lowest around for Short Lead Time for China Laser Pipe and Tube Cutting Machine Fiber Laser Pipe Cut CNC Laser Tube Cutting Machine, Our corporation is dedicated to giving customers with superior and secure excellent items at competitive rate, creating just about every customer content with our services and products.

Short Lead Time for China Tube Laser Cutting Machine, CNC Laser Cutting Machine, Our objects have national accreditation requirements for qualified, high quality products and solutions, affordable value, was welcomed by people today all over the world. Our goods will continue to enhance within the order and look forward to cooperation with you, Need to any of those goods be of interest to you, be sure to letus know. We’ve been gonna be content to offer you a quotation up on receipt of your detailed needs.

-

China Gold Supplier for China Steel Rust Remova...

-

China New Design China Good Quality Ipg Laser C...

-

OEM/ODM China China CNC Manufacturer Mini Porta...

-

Good Quality China 150W CO2 Tube Laser Engravin...

-

Good User Reputation for China High Efficiency ...

-

Factory Supply China Flat Bar H Beam Electric P...