Short Lead Time for 180w Co2 Laser Engraving Machine - 1390 1610 100W 150W CO2 Laser Engraving And Cutting Machine – Knoppo Detail:

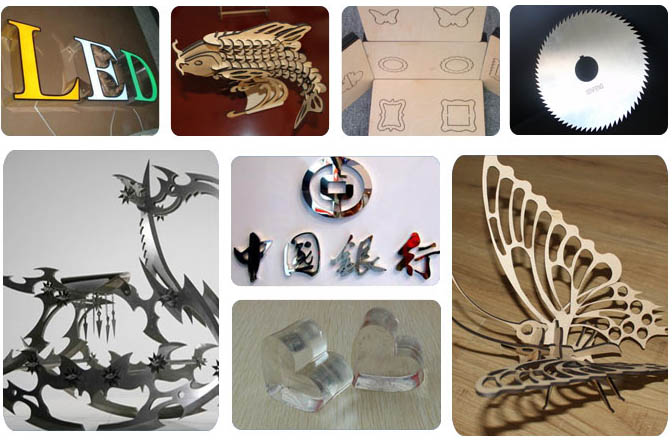

Application

Applicable Industry Of CO2 Laser Cutting Engraving Machine

Mould industry (construction mould, aviation and navigation mould, wooden mould), advertising signs, decoration, arts and crafts, electronics, electric appliances, etc.

Applicable Materials Of CO2 Laser Cutting Engraving Machine

Materials such as acrylic, wood planks(light planks, candlenut wood), bamboo ware, double color board, paper, leather, shell, coconut shell, ox horn, resin animal grease, ABS board, lamp shade, etc.

Techinical parameters

|

Model |

KCL-X |

|

Laser Power |

80W 100W 150W 180W 260W 300W |

|

Working Area |

600*900mm / 1300*900mm / 1600*1000mm |

|

Laser Type |

RECI CO2 Sealed Laser Tube ,10.6um |

|

Cooling Type |

Water Cooling |

|

Engraving Speed |

0-60000mm/min |

|

Cutting Speed |

0-40000mm/min |

|

Laser Output Control |

0-100% set by software |

|

Min. Engraving Size |

1.0mm*1.0mm |

|

Highest Scanning Precision |

4000DPI |

|

Locating Accuracy |

<= 0.05mm |

|

Controlling Software |

Ruida Control System |

|

Graphic Format Supported |

DST ,PLT, BMP ,DXF, DWG, AI ,LAS etc |

|

Compatible Software |

Illustrator , Photoshop , Coreldraw , Austocad , Solidworks etc |

|

Colour Separation |

Yes |

|

Drive System |

High precision 3-phase stepper motor |

|

Auxillary Equipment |

Exhaust Fan and Air Exhaust Pipe |

|

Power Supply |

AC 220V+10% , 50HZ |

|

Working Environment |

Temperature: 0~45C , Humidity :5~95% ( No Condensate Water ) |

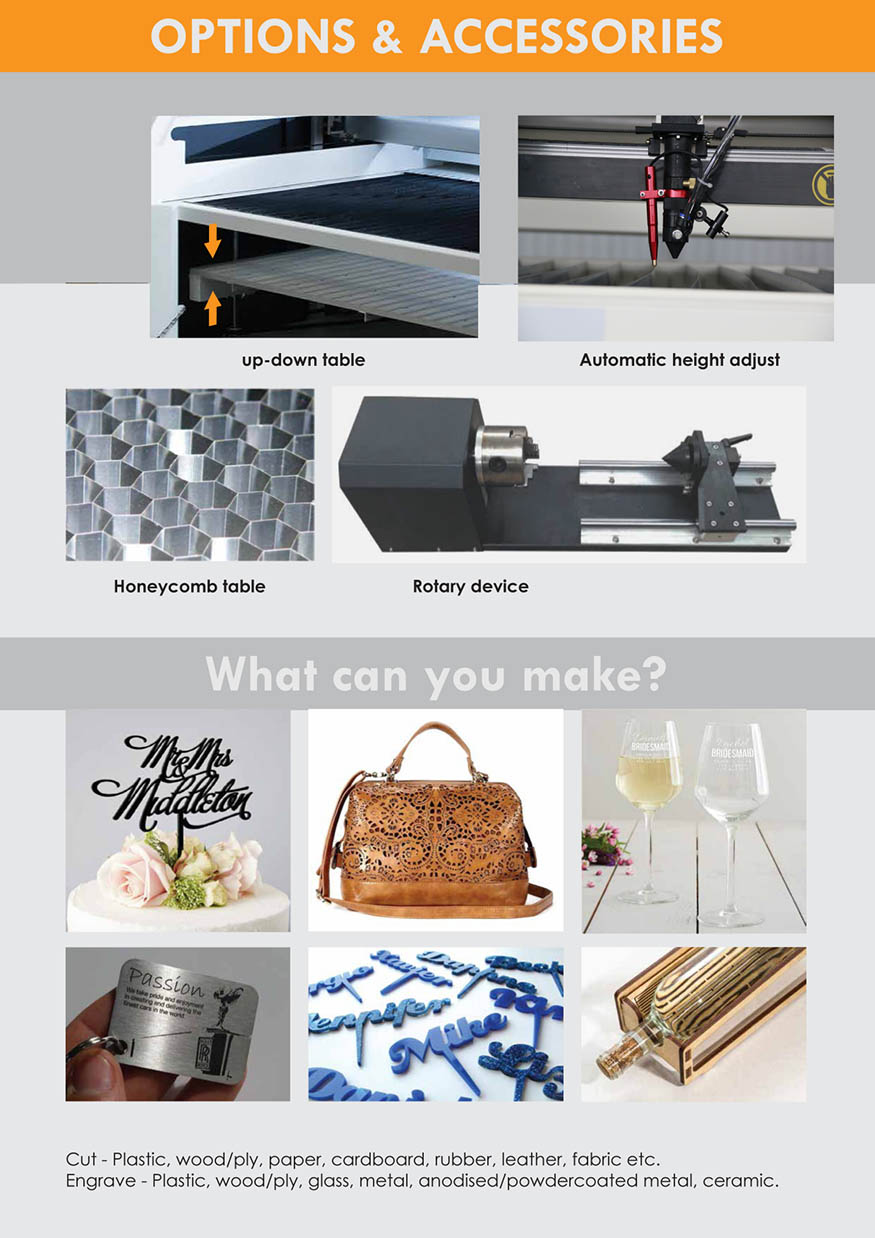

Configuration

Video

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Short Lead Time for 180w Co2 Laser Engraving Machine - 1390 1610 100W 150W CO2 Laser Engraving And Cutting Machine – Knoppo, The product will supply to all over the world, such as: United Kingdom, Belgium, Brunei, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

-

Factory Free sample 15000w Laser Cutting Machin...

-

18 Years Factory Fiber Laser Cutter Price - Me...

-

Discount wholesale Co2 Laser Cutting Engraving ...

-

OEM Supply Cnc Plasma Pipe Cutting Machine - 5...

-

High Quality Pipe Cutting - 6 Axis H Beam CNC ...

-

2020 Latest Design Steel Plasma Cutter - Metal...