Professional China H Beam Coping Machine - H beam fabrication line Automatic H beam cutting plasma robot machine – Knoppo Detail:

Application

Applicable Materials Of H Beam Cutting Machine

Cutting stainless steel, carbon steel, mild steel, iron. Cutting round pipe , square pipe, angle steel, steel channels, H beam, H-beam, H steel etc.

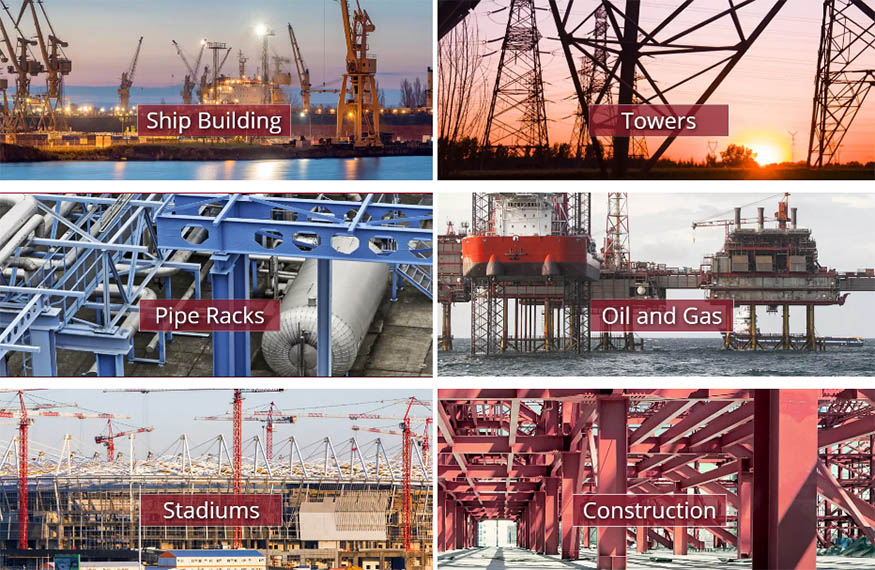

Applicable Industries Of H beam

metal fabrication, oild and gas pipe, steel construction, tower, train rail and other steel cutting fields.

Configuration

France Schneider Electrical Components

* The selection of branded spare parts technical services is guaranteed, and technical online service support.

Japan Panasonic Or Fuji Servo Motor

* High motion precision: It can realize the closed-loop control of position, speed and torque; overcome the problem of stepping motor out-of-step; read data in time with encoder feedback to compare the position.

* Speed: Good high-speed performance, generally rated speed can reach 1500-3000 rpm.

America Hypertherm Plasma Generator

No.1 Brand on the world, good cutting surface.

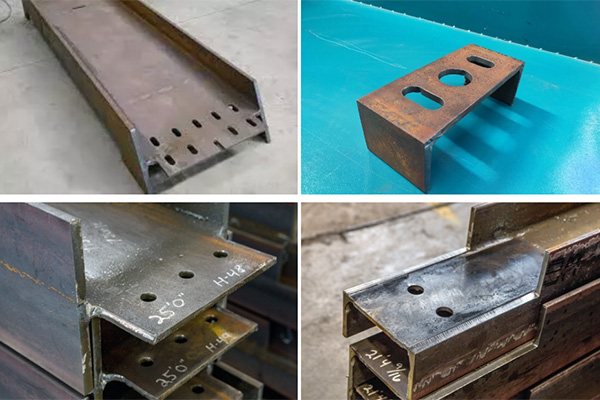

Good Bolt Hole Process

Instantaneously changes speeds and uses sophisticated software algorithms to produce straight through holes.

Techinical parameters

|

Model |

T400 |

|

Max Cutting Length |

6m / 9m / 12 m |

|

Min Cutting Length |

0.5 m |

|

Max Cutting Diamter |

430mm |

|

Min Cutting Diameter |

30mm |

|

Reposition precision |

0.02mm |

|

Processing precision |

0.1mm |

|

Maximum cutting speed |

12000mm/min |

|

Torch Height control mode |

Automatic |

|

Control system |

EOE-HZH |

|

Electrical Supplier |

380V 50HZ / 3 Phase |

Video

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Professional China H Beam Coping Machine - H beam fabrication line Automatic H beam cutting plasma robot machine – Knoppo, The product will supply to all over the world, such as: Brunei, Singapore, Nairobi, Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

-

Super Purchasing for Laser Metal Cutter - Full...

-

Super Purchasing for 6000w Fiber Laser Cutting ...

-

Hot Sale for 12000w Laser Cutter - Automatic M...

-

2020 Good Quality Pipe Cutter - Automatic CNC ...

-

Low MOQ for Tube Fiber Laser Cutting Machine -...

-

Manufacturing Companies for H Beam Hole Cutting...