We not only will try our greatest to offer you outstanding products and services to every single buyer, but also are ready to receive any suggestion offered by our buyers for Personlized Products China Cheap Automatic Feeding Auto-Loading Tube Pipe Fiber Laser Cutting Machine, We warmly welcome your participation dependant on mutual added benefits within the close to upcoming.

We not only will try our greatest to offer you outstanding products and services to every single buyer, but also are ready to receive any suggestion offered by our buyers for china fiber laser cutting machine, CNC Machine, Strong infrastructure is the need to have of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our solutions worldwide. To maintain smooth work flow, now we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we’re able to accomplish voluminous production without compromising on the quality.

Video

Features

1. Excellent beam quality: smaller spot size, higher work efficiency and better processing quality;

2. Fast cutting speed: about twice the cutting speed of CO2 laser machine or plasma cutting machine ;

3. High performance : the stable performance was acquired through the application of world’s top fiber laser source which makes it possible to cut at any point with equal quality through fiber transmission.

4. High electrical conversion efficiency: fiber laser cutting machine has 3 times higher electro-optical conversion efficiency than CO2 laser cutting machine, saving energy and protecting environment.

5. Low maintenance cost: fiber transmission without using reflective lenses saves a lot of time in optical path adjustment and achieves maintenance-free results.

Techinical parameters

|

Model |

KF3015 , KF4020 , KF6015 , KF6020 ,KF6025 |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W / 6000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

|

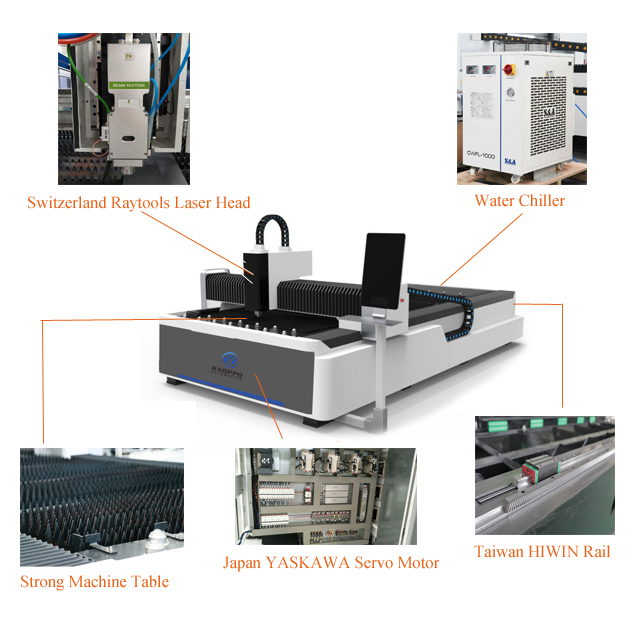

Laser Head |

Switzerland Raytools |

|

Laser Source |

Raycus / MAX / IPG |

|

System |

CYPCUT |

|

Servo Motor |

Japan Yaskawa |

|

Servo Driver |

Japan Yaskawa |

|

Water Chiller |

S&A |

Cutting parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

|

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

|

|

16 |

|

|

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|

|

18 |

|

|

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|

|

20 |

|

|

|

0.5–0.8 |

0.5–0.8 |

|

|

22 |

|

|

|

0.3–0.7 |

0.4–0.8 |

|

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

|

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

|

|

8 |

|

|

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|

|

10 |

|

|

|

0.6–0.8 |

0.8–1.2 |

|

|

12 |

|

|

|

0.4–0.6 |

0.5–0.8 |

|

|

14 |

|

|

|

|

0.4–0.6 |

|

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

|

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

|

|

5 |

|

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

|

|

6 |

|

|

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|

|

8 |

|

|

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|

|

10 |

|

|

|

0.4–0.7 |

0.6–1.2 |

|

|

12 |

|

|

|

0.3-0.45 |

0.4–0.6 |

|

|

16 |

|

|

|

|

0.3–0.4 |

|

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

|

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

|

|

5 |

|

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

|

|

6 |

|

|

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|

|

8 |

|

|

|

0.5–0.7 |

0.7–1.2 |

|

|

10 |

|

|

|

|

0.2–0.5 |

|

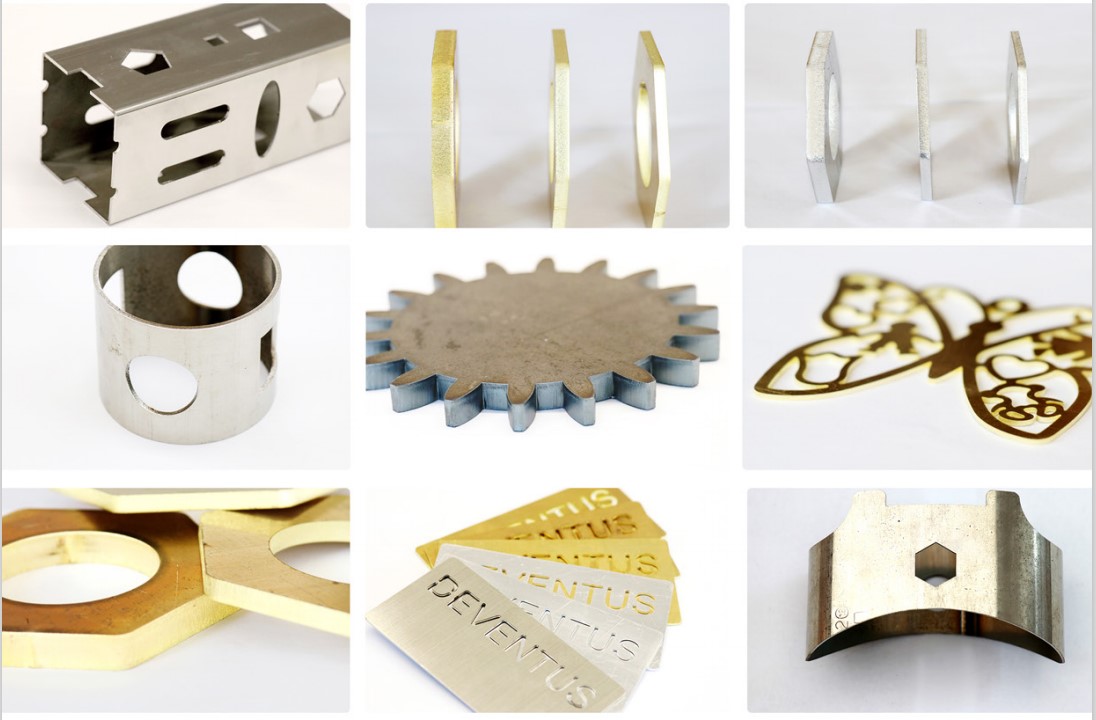

Sample

We not only will try our greatest to offer you outstanding products and services to every single buyer, but also are ready to receive any suggestion offered by our buyers for Personlized Products China Cheap Automatic Feeding Auto-Loading Tube Pipe Fiber Laser Cutting Machine, We warmly welcome your participation dependant on mutual added benefits within the close to upcoming.

Personlized Products China Fiber Laser Cutting Machine, CNC Machine, Strong infrastructure is the need to have of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our solutions worldwide. To maintain smooth work flow, now we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we’re able to accomplish voluminous production without compromising on the quality.

-

High reputation China Stainless Steel Aluminium...

-

Chinese Professional Favorable Price China Meta...

-

Cheap price China High Precision 2000W 3000W En...

-

Factory Price China High Efficiency CE, GS Appr...

-

Supply ODM Vmade CE Certificated China Factory ...

-

Fast delivery China CNC Stainless Steel Fiber L...