abide by the contract”, conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients’ satisfaction for OEM/ODM Factory China 1500W CNC Sheet Metal Plate Fiber Laser Cutting Machine Fiber Laser Cutting Machine Cutter Stainless Steel Carbon 1000W, Great top quality, competitive prices, prompt delivery and dependable services are guaranteed Kindly let’s know your quantity requirement under each size category so that we can inform you accordingly.

abide by the contract”, conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients’ satisfaction for China Fiber Laser Cutter Price, Fiber Laser CNC Machine, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

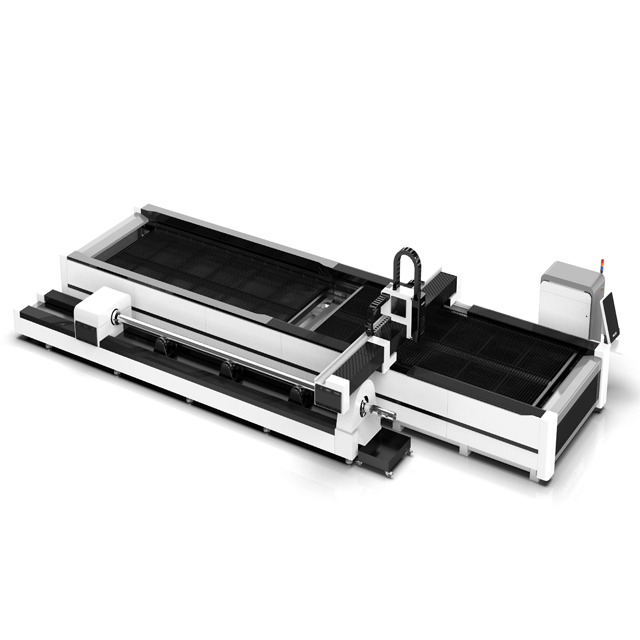

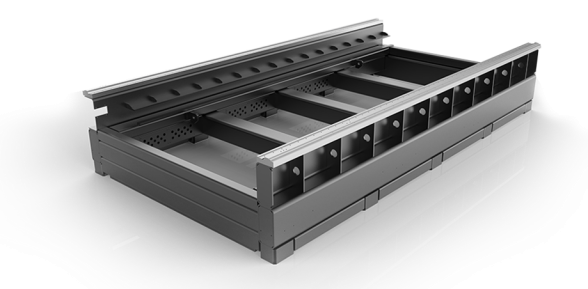

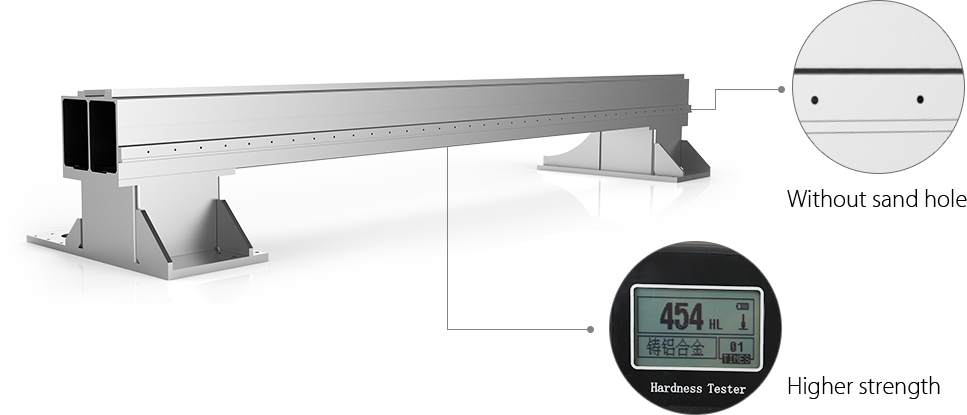

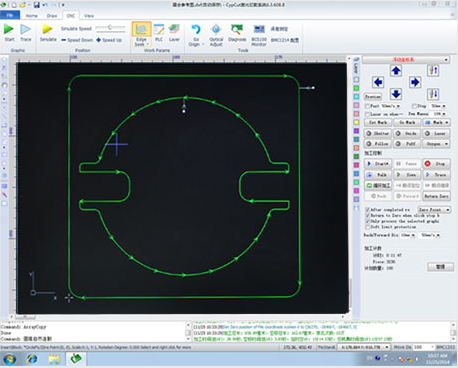

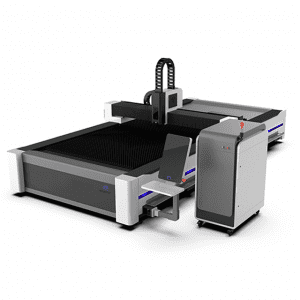

Main Features of KF-T Series dual used fiber laser cutter:

1. BETTER CUTTING QUALITY

Laser has a narrower kerf, meaning less material is wasted. More than this, laser cutting requires less manpower and even no secondary processing for most parts.

2.HIGHER CUTTING PRECISION

Laser cutting, 0.14mm; Plasma cutting, 0.4mm And at the vertical cross, laser cutting has a smaller bevel angle than plasma cutting.

3. LOWER CUTTING COSTS

Getting rid of secondary finishing, with smoother cutting surface, less dross, and smaller deformation.

4. FASTER CUTTING SPEED

Laser cutting speed can reach up to three times faster than plasma cutting.

5. ENVIRONMENT-FRIENDLY PROCESSING

Fiber laser cutting machine is cleaner and more environment-friendly than the smoky and noisy plasma cutting.

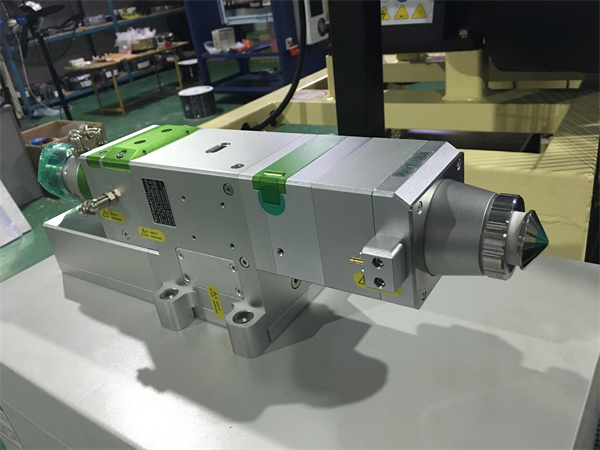

Configuration :

Techinical Parameters

|

Model |

KF-TSeries |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Tube Cutting Length |

3m / 6m |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W /6000W /8000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting Parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

||

|

16 |

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|||

|

18 |

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|||

|

20 |

0.5–0.8 |

0.5–0.8 |

||||

|

22 |

0.3–0.7 |

0.4–0.8 |

||||

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

||

|

8 |

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|||

|

10 |

0.6–0.8 |

0.8–1.2 |

||||

|

12 |

0.4–0.6 |

0.5–0.8 |

||||

|

14 |

0.4–0.6 |

|||||

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

||

|

5 |

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

||

|

6 |

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|||

|

8 |

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|||

|

10 |

0.4–0.7 |

0.6–1.2 |

||||

|

12 |

0.3-0.45 |

0.4–0.6 |

||||

|

16 |

0.3–0.4 |

|||||

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

||

|

5 |

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

||

|

6 |

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|||

|

8 |

0.5–0.7 |

0.7–1.2 |

||||

|

10 |

0.2–0.5 |

|||||

video

abide by the contract”, conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients’ satisfaction for OEM/ODM Factory China 1500W CNC Sheet Metal Plate Fiber Laser Cutting Machine Fiber Laser Cutting Machine Cutter Stainless Steel Carbon 1000W, Great top quality, competitive prices, prompt delivery and dependable services are guaranteed Kindly let’s know your quantity requirement under each size category so that we can inform you accordingly. 1000w cnc fiber laser cutting machine

OEM/ODM Factory China Fiber Laser Cutter Price, Fiber Laser CNC Machine, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

-

Cheap PriceList for China Logo and Ring CNC Fib...

-

Factory made hot-sale China Raycus Ipg Laser Cu...

-

Wholesale ODM China CE Approved 20W Desktop Fib...

-

ODM Factory China Remax High-Precision Heavy-Du...

-

Professional China China Max Raycus Laser Power...

-

China Gold Supplier for China CNC Flame Gantry ...