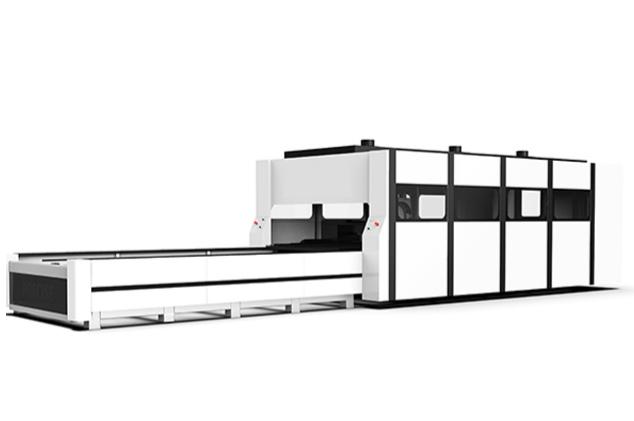

OEM China Reci Laser Cutting Machine - 4KW 6KW 8KW Steel CNC Fiber Laser Cutting Machine Price – Knoppo Detail:

Video

Application

Applicable Materials Of CNC Fiber Laser Cutting Machine

CNC fiber laser cutting machine can cut thick stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheet, metal plate.

Applicable Industries Of CNC Fiber Laser Cutting Machine

CNC fiber laser cutting machine is used for industry of machinery parts, electrics, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts, metal jewelry and other metal cutting fields.

Sample

Configuration

* Japan SMC Electric Proportional Valve.

*Positioning and re-positioning accuracy is 0.02mm.

* IPG , Raycus or Max laser source in 4KW, 6KW, 8KW, 10KW, 12KW, 15KW, 20KW, 30KW – Lifespan 100,000 hours.

* Precision German PRECITEC auto focus laser head.

* Ball screw drive guide rail system.

* German Rexroth Motor Driver.

*German Rexroth guide rails.

* German Schneider Electronics Parts.

* German BECKOFF software including nesting capability – stable and efficient productivity.

* Water chiller and extraction system included.

Techinical parameters

|

Model |

KP6020 |

|

Wavelength |

1070nm |

|

Cutting Area |

3000*1500mm, 4000*2000mm, 6000*2000mm, 6000*2500mm. |

|

Laser Power |

4KW, 6KW, 8KW, 10KW, 12KW, 15KW, 20KW |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting parameters

|

4000W |

6000W |

8000W |

12000W |

15000W |

||

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8–10 |

8–10 |

8–10 |

9–11 |

9–11 |

|

2 |

5–7.5 |

5–7.5 |

5–7.5 |

5–7.5 |

5–7.5 |

|

|

3 |

3.5–5.0 |

3.5–5 |

3.5–5 |

3.5–5.5 |

3.5–5.5 |

|

|

4 |

3.0–4.0 |

3.0–4.5 |

3.0–4.5 |

3.5–5 |

3.5–5 |

|

|

5 |

2.7–3.6 |

3.0–4.2 |

3.0–4.2 |

3.3–4.8 |

3.3–4.8 |

|

|

6 |

2.5–3.4 |

2.5–3.5 |

2.6–3.7 |

3.0–4.2 |

3.0–4.2 |

|

|

8 |

2.0–3.0 |

2.2–3.2 |

2.3–3.5 |

2.5–3.5 |

2.5–3.5 |

|

|

10 |

1.5–2.4 |

1.8–2.5 |

2–2.5 |

2.2–2.7 |

2.2–2.7 |

|

|

12 |

1.2–1.8 |

1.2–2.0 |

1.2–2.1 |

1.2–2.1 |

1.2–2.1 |

|

|

14 |

0.9–1.2 |

1.2–1.8 |

1.2–1.9 |

1.7–1.9 |

1.5–1.9 |

|

|

16 |

0.8–1.0 |

0.8–1.3 |

0.8–1.5 |

1.2–1.7 |

1.2–1.7 |

|

|

18 |

0.6–0.9 |

0.6–0.9 |

0.8–1.5 |

1.0–1.8 |

1.2–1.5 |

|

|

20 |

0.5–0.8 |

0.5–0.8 |

0.6–1.3 |

0.6–1.5 |

1.2–1.5 |

|

|

22 |

0.4–0.8 |

0.4–0.8 |

0.5–0.8 |

0.5–1.5 |

1.0–1.5 |

|

|

25 |

|

0.3–0.55 |

0.3–0.7 |

0.5–1.1 |

0.8–1.5 |

|

|

30 |

|

|

0.2–0.7 |

0.3–0.9 |

0.6–1.0 |

|

|

35 |

|

|

|

0.3–0.5 |

0.4–0.6 |

|

|

40 |

|

|

|

0.2–0.4 |

0.3–0.5 |

|

|

45 |

|

|

|

|

0.2–0.5 |

|

|

50 |

|

|

|

|

0.1–0.5 |

|

|

Stainless steel |

1 |

32–45 |

42–52 |

50–65 |

70–85 |

72–100 |

|

2 |

16–28 |

20–33 |

30–40 |

40–66 |

45–70 |

|

|

3 |

7.0–15 |

15–22 |

18–27 |

35–45 |

38–50 |

|

|

4 |

5.0–8.0 |

10–15 |

12–16 |

20–32 |

25–35 |

|

|

5 |

3.5–5.0 |

8.0–12 |

10–15 |

18–25 |

20–30 |

|

|

6 |

2.5–4.5 |

4.8–8.0 |

6.0–10.0 |

12–15 |

15.0–25.0 |

|

|

8 |

1.2–2.0 |

3.0–4.0 |

3.5–5.0 |

8–12 |

8.0–12.0 |

|

|

10 |

0.8–1.2 |

1.6–2.5 |

2.0–2.7 |

6.0–8.0 |

6.0–10.0 |

|

|

12 |

0.5–0.8 |

0.8–1.5 |

1.2–2.0 |

4.0–5.5 |

4.0–6.0 |

|

|

14 |

0.4–0.6 |

0.6–0.8 |

1.2–1.8 |

3.0–5.0 |

3.5–6.0 |

|

|

16 |

|

0.5–0.8 |

1.0–1.6 |

2.2–2.8 |

2.5–3.0 |

|

|

18 |

|

0.4–0.6 |

0.8–1.2 |

1.2–2.0 |

1.2–2.2 |

|

|

20 |

|

0.3–0.5 |

0.4–0.7 |

1.0–1.6 |

1.3–1.8 |

|

|

25 |

|

0.2–0.4 |

0.3–0.5 |

0.5–0.8 |

0.6–1.2 |

|

|

30 |

|

|

0.2–0.4 |

0.3–0.6 |

0.5–1.0 |

|

|

35 |

|

|

|

0.3–0.5 |

0.4–0.8 |

|

|

40 |

|

|

|

0.3–0.5 |

0.3–0.6 |

|

|

45 |

|

|

|

0.2–0.4 |

0.2–0.5 |

|

|

50 |

|

|

|

0.1–0.2 |

0.1–0.5 |

|

|

60 |

|

|

|

|

0.1-0.2 |

|

|

70 |

|

|

|

|

0.05–0.1 |

|

|

Aluminum |

1 |

35–45 |

42–55 |

48–65 |

60–85 |

70–100 |

|

2 |

13–24 |

20–40 |

25–48 |

38–50 |

40–55 |

|

|

3 |

7.0–13 |

15–25 |

20–33 |

30–40 |

35–45 |

|

|

4 |

4.0–5.5 |

9.5–12 |

13–18 |

20–30 |

30–40 |

|

|

5 |

3.0–4.5 |

5.0–8.0 |

9.0–12 |

15–25 |

20–30 |

|

|

6 |

2.0–3.5 |

3.8–5.0 |

4.5–8.0 |

10–15 |

15–24 |

|

|

8 |

0.9–1.6 |

2.0–2.5 |

4.0–5.5 |

7.0–12 |

8.0–12.0 |

|

|

10 |

0.6–1.2 |

1.0–1.5 |

2.2–3.0 |

4.5–8.0 |

6.0–10.0 |

|

|

12 |

0.4–0.6 |

0.8–1.0 |

1.5–1.8 |

4.0–5.0 |

4.0–6.0 |

|

|

16 |

0.3–0.4 |

0.5–0.8 |

1.0–1.6 |

1.5–2.5 |

2.0–3.0 |

|

|

20 |

|

0.5–0.7 |

0.7–1.0 |

0.9–1.5 |

1.3–1.8 |

|

|

25 |

|

0.3–0.5 |

0.4–0.7 |

0.6–0.9 |

0.6–1.2 |

|

|

30 |

|

|

0.3–0.6 |

0.3–0.8 |

0.5–1.0 |

|

|

35 |

|

|

|

0.3–0.6 |

0.3–0.8 |

|

|

40 |

|

|

|

0.2–0.4 |

0.2–0.5 |

|

|

50 |

|

|

|

0.1–0.2 |

0.3–0.7 |

|

|

60 |

|

|

|

|

0.2–0.5 |

|

|

Brass |

1 |

25–35 |

35–45 |

40–55 |

55–65 |

75–85 |

|

2 |

8.0–12 |

20–30 |

28–40 |

38–50 |

40–55 |

|

|

3 |

5.0–8.0 |

12–18 |

20–30 |

20–30 |

32–50 |

|

|

4 |

3.2–5.5 |

5.0–8.0 |

10–15 |

15–20 |

27–35 |

|

|

5 |

2.0–3.0 |

4.5–6.0 |

6.0–9.0 |

10–15 |

18–26 |

|

|

6 |

1.4–2.0 |

3.0–4.5 |

4.5–6.5 |

6.0–8.0 |

10–18 |

|

|

8 |

0.7–1.2 |

1.6–2.2 |

2.4–4.0 |

5.0–7.0 |

8.0–10.0 |

|

|

10 |

0.2–0.5 |

0.8–1.2 |

1.5–2.2 |

4.5–6.5 |

5.0–7.0 |

|

|

12 |

|

0.3–0.5 |

0.8–1.2 |

2.4–4.0 |

2.8–4.2 |

|

|

14 |

|

0.3–0.4 |

0.4–0.6 |

0.8–1.5 |

1.0–1.8 |

|

|

16 |

|

|

0.3–0.5 |

0.6–1.2 |

0.8–1.5 |

|

|

18 |

|

|

|

0.4–0.6 |

0.6–0.8 |

|

|

20 |

|

|

|

0.3–0.5 |

0.4–0.6 |

|

|

25 |

|

|

|

|

0.3–0.5 |

|

Product detail pictures:

Related Product Guide:

We goal to see good quality disfigurement within the manufacturing and provide the most effective support to domestic and overseas shoppers wholeheartedly for OEM China Reci Laser Cutting Machine - 4KW 6KW 8KW Steel CNC Fiber Laser Cutting Machine Price – Knoppo, The product will supply to all over the world, such as: Casablanca, Canada, Argentina, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information and we will offer you competitive price list then.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

-

2020 High quality Hand-Held Laser Welder - 100...

-

Online Exporter 120w Laser Cutter - KF3015P Fu...

-

New Arrival China 500w Fiber Laser Cleaning Mac...

-

Factory directly supply 120a Plasma Cutter - C...

-

China Gold Supplier for Fiber Lathe Metal Cutti...

-

Chinese wholesale Fiber Laser Welder - 1000W 1...