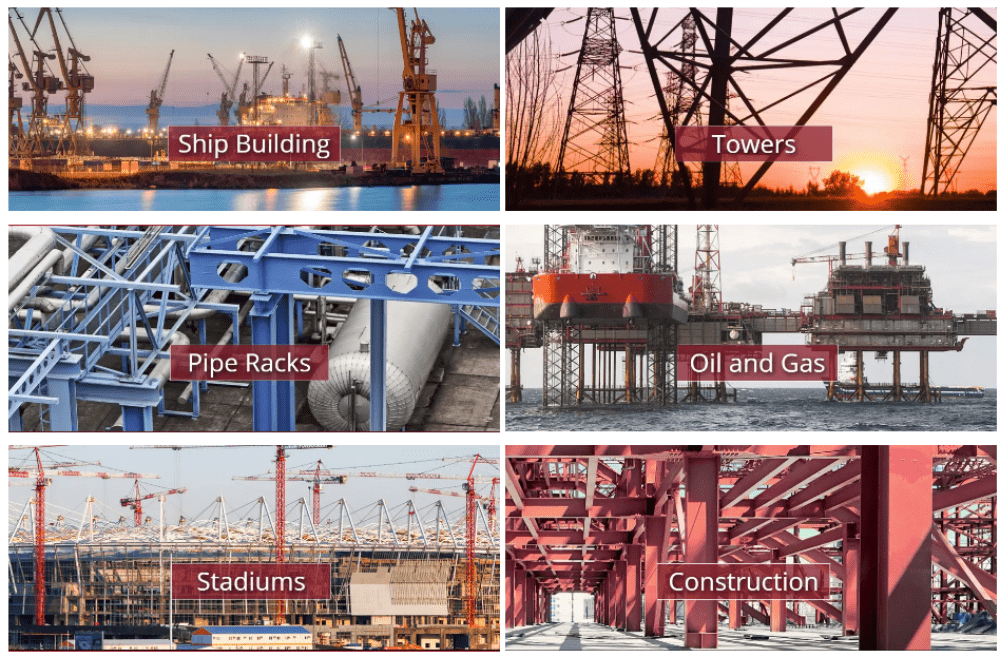

In recent years, plasma cutting technology saw a fast development in metal fabrication industry. Steel pipe or H beam are the main material for metal fabrication, and plasma cutting can replace some die cutting methods using complex large mold, greatly reducing production time and lowering costs.

At present, the main unloading methods for steel pipe or beam are plasma cutting. With the development of plasma technology , it have a good advantages ,

beasutiful cutting surface , automatic nesting and automatic feeding etc , save customer time and labor cost .

China Koppo Company have 3 model pipe plasma cutting machine , First is RT400 10 axis plasma cutting robot , this machine have auto feeding system ,

10 axis plasma cutting robot can cut pipe or beam pieces by 360 degree without rotary .

Second is T400 8 axis plasma cutting machine , this machine is automatic rotary and chuck , when machine cut pipe or beam , this machine can auto feeding , rotary and cut .

Third is T300 5 axis plasma cutting machine , similar with T400 8 axis plasma cutting machine , difference is that this machine can not bevel cutting and H beam cutting .

Although the COVID-19 pandemic around the world , metal fabrication industry is still boom , Our 3 models pipe plasma cutting machine is exported to Europe , Australia , South Africa , Korea , Vietnam and Indonesia etc , very popular .

As a leader in the China market of pipe plasma cutting machine , In 2020, it was precisely because of insistence and beliefs that we turned COVID-19 crises into opportunities. In 2021, we have reason to believe that KNOPPO will continue to get burnishing both home and abroad. What goes down must come up. In tough times during COVID-19 , beliefs lights up our future and dream guides our way forward. So when you look back at your tough times and feel worried, please hold your beliefs and go on.

Post time: Jun-09-2021