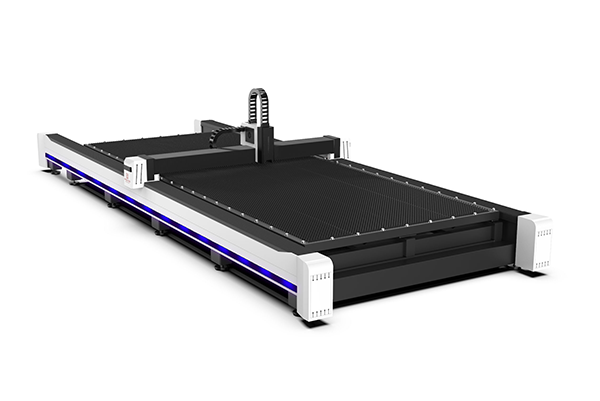

In some heavy metal processing industries, such as the shipbuilding industry, mining machinery, and construction machinery, such problems are often encountered: how to achieve solid welding of metal parts and metal parts? Usually, the metal parts will show a cut surface after the general cutting process. In order to make the interface parts of the welded parts more integrated, it is necessary to process the bevels of various geometric shapes on the edges of the two pieces of metal, and then perform end face welding. Recently, Knoppo has launched KP Series (power from 30000W to 8000W) Sheet fiber laser bevel cutting machine, which will solve such welding problems, reduce cumbersome processes, and greatly save time and cost.

Before fiber laser cutting technology, bevel cutting technology was also used in metal sheet processing methods such as flame and plasma cutting. However, the traditional flame cutting method will produce deep cuts, and for complex groove trajectories, the proficiency and working state of the workers need be very professional , and the consistency of welding cannot be well satisfied; plasma cutting Wide, resulting in low dimensional accuracy, and hazards such as arc radiation, smoke and noise will be generated during the cutting process.

The above two types of cutting methods belong to the large heat source input processing method. The plate will be thermally deformed under the thermal processing method, and the inverse deformation process needs to be processed after the processing is completed. Compared with the traditional beveling method, laser is a new processing method with the smallest thermal deformation, the best incision quality, the highest dimensional accuracy and the best stability in the market.

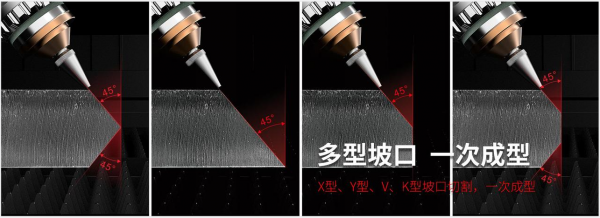

Knoppo KP series sheet fiber laser beveling cutting machine can greatly improve the welding firmness, welding fusion and workpiece aesthetics by processing the groove of a certain geometric shape in the to-be-welded part of the weldment. For alloy steel, the groove can also play a role in adjusting the ratio of base metal and filler metal.

According to the different thickness and physical properties of different plates, the choice of beveling forms is also different. Common beveling forms on the market include X-shaped groove, V-shaped groove, Y-shaped groove, K-shaped groove, etc. Y-shaped groove and V-shaped groove are single-sided welding, which is convenient for cutting and post-welding process. When the thickness of the weldment increases, the K-shaped groove or the X-shaped groove is generally used. At the same thickness, the amount of weld metal can be reduced by about 1/2, and the welding is symmetrical, and the deformation after welding is small.

What is knoppo fiber laser beveling cutting machine ?

First, the groove of a certain geometric shape can be directly processed at the to-be-welded part of the weldment, so that the welding seam with full penetration of the welding thickness can be obtained in the subsequent welding process, so as to ensure the welding strength of the weldment and reduce unnecessary processes. , to achieve a multiplier effect;

Second, compared with traditional flame and plasma bevel processing, laser processing is more efficient and saves materials. For example, in the shipbuilding industry, the use of laser bevel cutting technology to process T-shaped components of low alloy steel can greatly save alloy steel materials while ensuring the stability of the ship;

Third, laser processing has the advantages of small thermal deformation, stable cutting quality and high precision. Good splicing.

At present, Knoppo laser bevel cutting technology has achieved full coverage in sheet metal processing and profile processing, and the technology has a wide range of applications, covering shipbuilding, industrial refrigeration, construction machinery, mining machinery, oil pipelines, etc.

Post time: Jul-08-2022