There are many methods for metal welding, such as traditional argon arc welding, electric welding and other ordinary welding machines.

In the past of few years, laser cutting and laser welding have entered the field of metal processing and forming. The high efficiency and convenience of hand-held laser welding machines are obvious, and the “metal welding iteration effect” is quickly produced, which can almost replace argon arc welding, electric welding and other processes. It can be used in door and window hardware, handicrafts, lighting, metal advertising, hardware kitchen and bathroom, tableware, kitchen appliances, agricultural and forestry machinery, medical equipment, sports fitness equipment, construction machinery and other industries.

1. Knoppo Laser provide combined solution of metal cutting , metal bending and metal welding . For example , fiber laser welding machine , CNC bending machine and fiber laser welding machine , that can help customer to produce beautiful products .

2.The hand-held laser welder improves welding defects such as undercut, incomplete penetration, dense pores and cracks that occur in the traditional welding process. The welded seam after welding is smooth and beautiful, which reduces the subsequent grinding process and saves time and cost. And there are few consumables, long life, and it can be flexibly suitable for various environments.

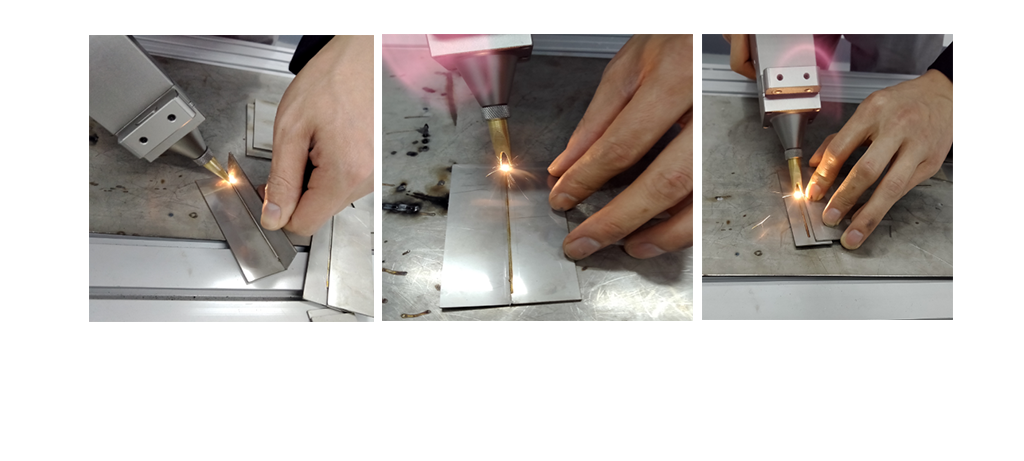

1). Simply set the parameters and you can get started immediately. After replacing the nozzle, it is easy to do flat welding, internal angle, external angle, overlap welding, etc.

2). The laser beam is uniform, high quality, continuous and stable, and evenly irradiated. The welding effect is the same whether you are a novice or a skilled hand. 3. There will be no problems such as pores, weld bead, weld penetration, and workpiece deformation.

3). For metal materials such as stainless steel, galvanized sheet, cold plate, etc., it can basically realize one-time rapid welding, which is several times faster than other welding methods.

3. Knoppo Handheld Laser Welding Machine is an innovative equipment that replaces traditional welding. It has a fast welding speed, which is about 5-10 times faster than traditional welding. The equipment is easy to operate, and the welding efficiency is high. One machine can save at least 2 welders every year, and the laser has a long service life (more than 100,000 hours). Can greatly reduce equipment costs and labor costs.

4. Advantages of Knoppo fiber laser welding machine :

1). Simple, easy to learn, flexible and convenient. Adopting an integrated structure, the operator is not demanding, simple training can be used, simple operation, quick to get started; multi-dimensional welding, flexible and convenient;

2). Low input cost and maintenance cost. Hand-held laser welding, no need for a fine welding table, less consumables, low equipment deployment and maintenance costs, and high cost performance;

3). Save labor. Hand-held laser welding is fast, 5-10 times faster than traditional welding, and one machine can save at least 2 welders a year; the weld seam after welding is smooth and beautiful, reducing the subsequent polishing process, saving time and cost;

4). Good quality. The laser welding workpiece has no deformation, no welding scar, and the welding is firm;

5). Safety protection. It has a contact type safety protection function to avoid accidental light emission and ensure that light can only be welded after contact with metal. Equipped with laser protective glasses, which need to be worn when welding. To ensure safety.

Post time: Dec-15-2021