New Fashion Design for Steel Plasma And Flame Cutting Machine - H beam fabrication line Automatic H beam cutting plasma robot machine – Knoppo Detail:

Application

Applicable Materials Of H Beam Cutting Machine

Cutting stainless steel, carbon steel, mild steel, iron. Cutting round pipe , square pipe, angle steel, steel channels, H beam, H-beam, H steel etc.

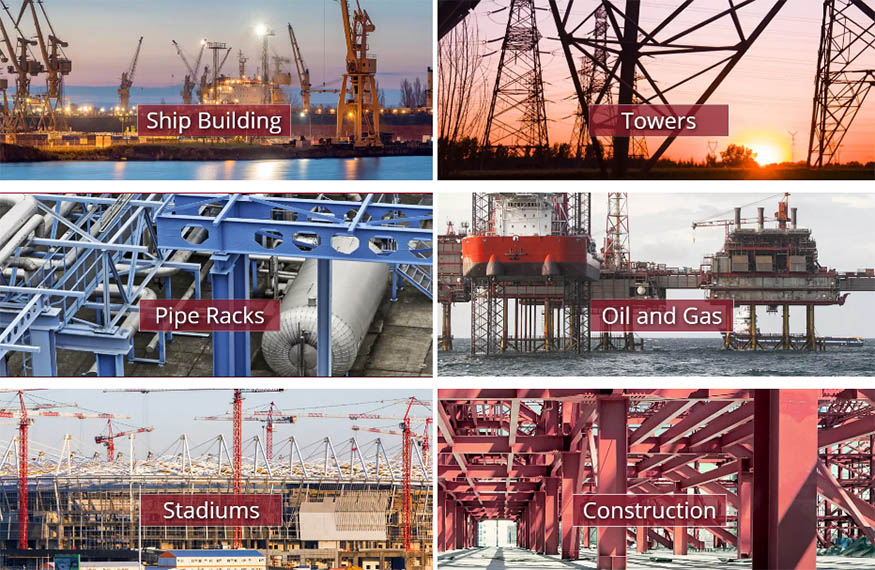

Applicable Industries Of H beam

metal fabrication, oild and gas pipe, steel construction, tower, train rail and other steel cutting fields.

Configuration

France Schneider Electrical Components

* The selection of branded spare parts technical services is guaranteed, and technical online service support.

Japan Panasonic Or Fuji Servo Motor

* High motion precision: It can realize the closed-loop control of position, speed and torque; overcome the problem of stepping motor out-of-step; read data in time with encoder feedback to compare the position.

* Speed: Good high-speed performance, generally rated speed can reach 1500-3000 rpm.

America Hypertherm Plasma Generator

No.1 Brand on the world, good cutting surface.

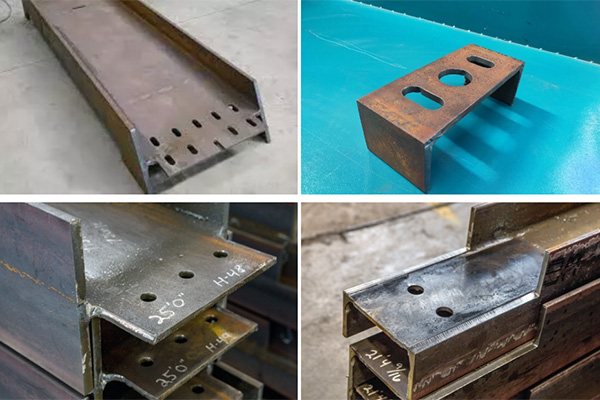

Good Bolt Hole Process

Instantaneously changes speeds and uses sophisticated software algorithms to produce straight through holes.

Techinical parameters

|

Model |

T400 |

|

Max Cutting Length |

6m / 9m / 12 m |

|

Min Cutting Length |

0.5 m |

|

Max Cutting Diamter |

430mm |

|

Min Cutting Diameter |

30mm |

|

Reposition precision |

0.02mm |

|

Processing precision |

0.1mm |

|

Maximum cutting speed |

12000mm/min |

|

Torch Height control mode |

Automatic |

|

Control system |

EOE-HZH |

|

Electrical Supplier |

380V 50HZ / 3 Phase |

Video

Product detail pictures:

Related Product Guide:

We always get the job done to be a tangible staff to ensure that we can easily offer you the best high-quality and the greatest value for New Fashion Design for Steel Plasma And Flame Cutting Machine - H beam fabrication line Automatic H beam cutting plasma robot machine – Knoppo, The product will supply to all over the world, such as: Swedish, Hanover, Bangladesh, We firmly think that we have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

-

Fast delivery Logo Laser Marking Machine - 50W...

-

18 Years Factory 100w Co2 Laser Engraving Machi...

-

Reliable Supplier 1500w Fiber Laser Cutter - O...

-

Fast delivery Logo Laser Marking Machine - KML...

-

Top Suppliers 12kw Fiber Laser - 4KW 6KW 8KW S...

-

Professional China Cnc Plasma - Robotic CNC pl...