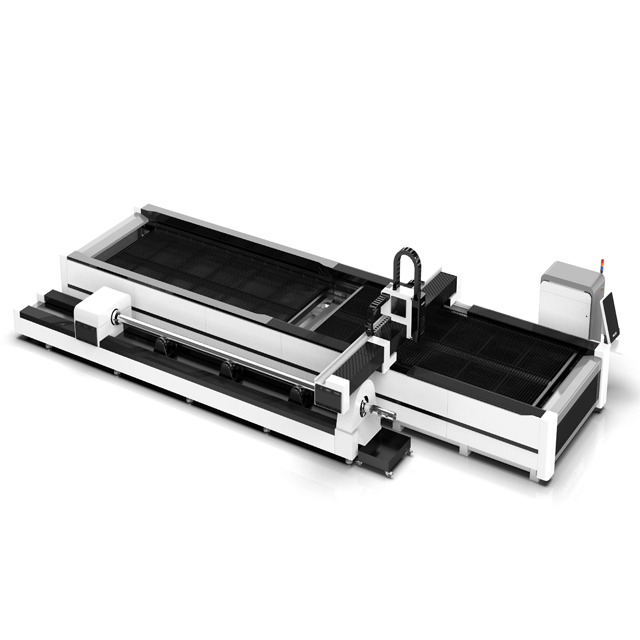

We insist over the principle of development of ‘High top quality, Performance, Sincerity and Down-to-earth working approach’ to supply you with exceptional services of processing for High definition China 1000W Fiber Laser Cutting Machine (3015 1530) for Metal Sheet Aluminum, We consider in top quality more than quantity. Before export in the hair there is strict quality control check during treatment as per international excellent standards.

We insist over the principle of development of ‘High top quality, Performance, Sincerity and Down-to-earth working approach’ to supply you with exceptional services of processing for china laser cutting machine, metal cutting machine, Now the competition in this field is very fierce; but we are going to still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. “Change for the better!” is our slogan, which means “A better world is before us, so let’s enjoy it!” Change for the better! Are you ready?

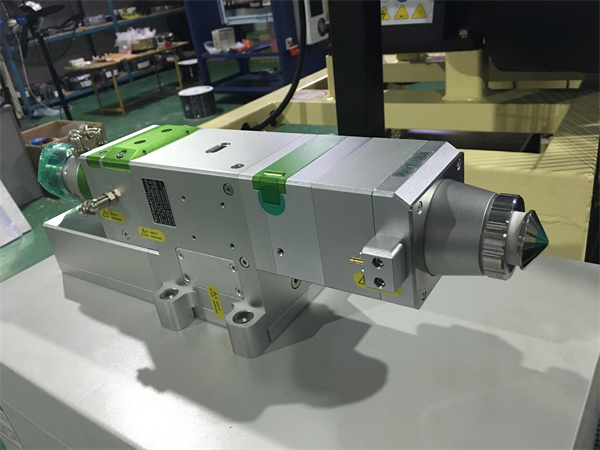

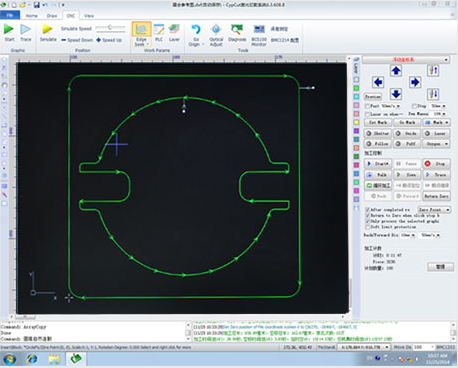

Main Features of KF-T Series dual used fiber laser cutter:

1. BETTER CUTTING QUALITY

Laser has a narrower kerf, meaning less material is wasted. More than this, laser cutting requires less manpower and even no secondary processing for most parts.

2.HIGHER CUTTING PRECISION

Laser cutting, 0.14mm; Plasma cutting, 0.4mm And at the vertical cross, laser cutting has a smaller bevel angle than plasma cutting.

3. LOWER CUTTING COSTS

Getting rid of secondary finishing, with smoother cutting surface, less dross, and smaller deformation.

4. FASTER CUTTING SPEED

Laser cutting speed can reach up to three times faster than plasma cutting.

5. ENVIRONMENT-FRIENDLY PROCESSING

Fiber laser cutting machine is cleaner and more environment-friendly than the smoky and noisy plasma cutting.

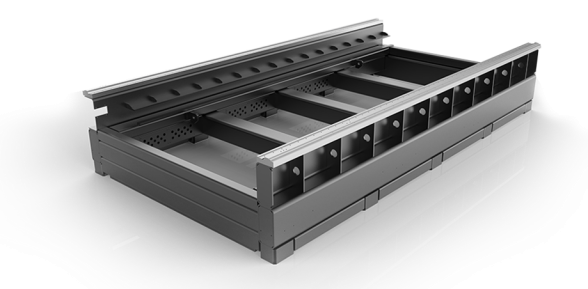

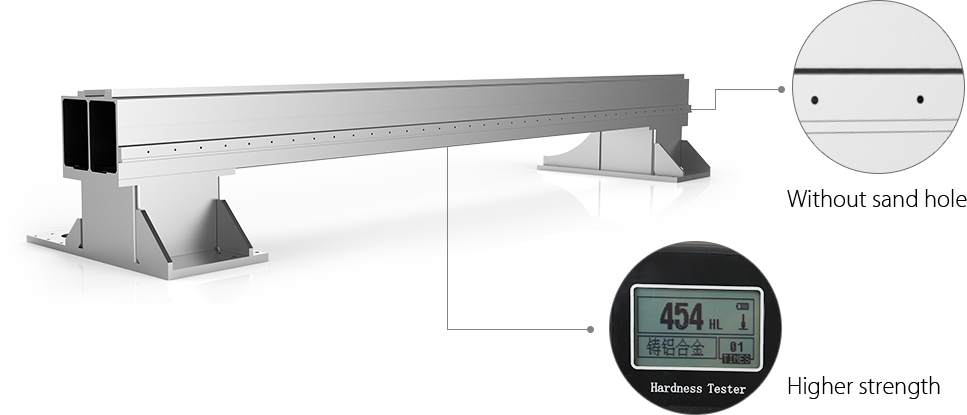

Configuration :

Techinical Parameters

|

Model |

KF-TSeries |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Tube Cutting Length |

3m / 6m |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W /6000W /8000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting Parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

||

|

16 |

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|||

|

18 |

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|||

|

20 |

0.5–0.8 |

0.5–0.8 |

||||

|

22 |

0.3–0.7 |

0.4–0.8 |

||||

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

||

|

8 |

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|||

|

10 |

0.6–0.8 |

0.8–1.2 |

||||

|

12 |

0.4–0.6 |

0.5–0.8 |

||||

|

14 |

0.4–0.6 |

|||||

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

||

|

5 |

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

||

|

6 |

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|||

|

8 |

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|||

|

10 |

0.4–0.7 |

0.6–1.2 |

||||

|

12 |

0.3-0.45 |

0.4–0.6 |

||||

|

16 |

0.3–0.4 |

|||||

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

||

|

5 |

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

||

|

6 |

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|||

|

8 |

0.5–0.7 |

0.7–1.2 |

||||

|

10 |

0.2–0.5 |

|||||

video

We insist over the principle of development of ‘High top quality, Performance, Sincerity and Down-to-earth working approach’ to supply you with exceptional services of processing for High definition China 1000W Fiber Laser Cutting Machine (3015 1530) for Metal Sheet Aluminum, We consider in top quality more than quantity. Before export in the hair there is strict quality control check during treatment as per international excellent standards.

High definition China Laser Cutting Machine, Metal Cutting Machine, Now the competition in this field is very fierce; but we are going to still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. “Change for the better!” is our slogan, which means “A better world is before us, so let’s enjoy it!” Change for the better! Are you ready?

-

18 Years Factory China Auto Focus 20W 30W 50W F...

-

High reputation China Factory Most Cost Effecti...

-

100% Original China 9060 1390 Reci 60W 80W 100W...

-

Wholesale China 2000W 3000W 4000W 6000W 8000W 1...

-

CE Certificate Vibration Poishing Machine Debur...

-

Chinese wholesale China Square Pipe Fiber Laser...