Factory Free sample Steel Channels Cutting Machine - Robotic CNC plasma pipe profile cutting machine for square tube – Knoppo Detail:

Application

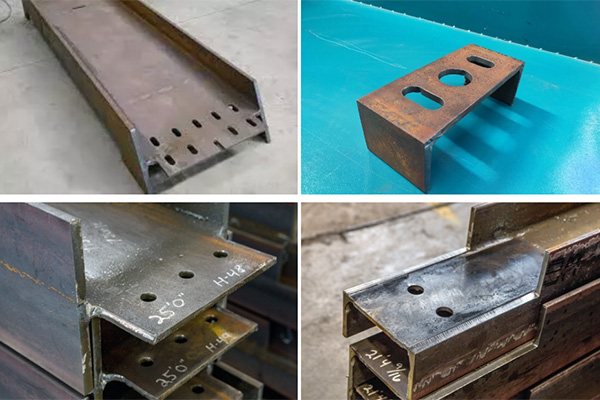

Applicable Materials Of Plasma Cutting Robot

Cutting stainless steel, carbon steel, mild steel, iron. Cutting round pipe, square pipe, angle steel, steel channels, H beam, H-beam, H steel etc.

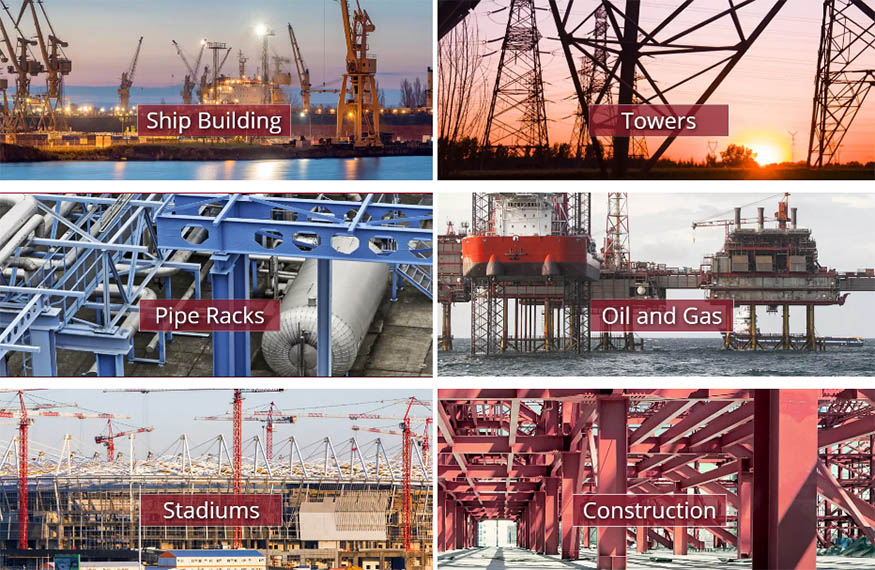

Applicable Industries Of Plasma Cutting Machine

metal fabrication, oild and gas pipe, steel construction, tower, train rail and other steel cutting fields.

Configuration

France Schneider Electrical Components

* The selection of branded spare parts technical services is guaranteed, and technical online service support.

Japan Panasonic Or Fuji Servo Motor

* High motion precision: It can realize the closed-loop control of position, speed and torque; overcome the problem of stepping motor out-of-step; read data in time with encoder feedback to compare the position.

* Speed: Good high-speed performance, generally rated speed can reach 1500-3000 rpm.

10 Axis Robotic Arm

Cuts, Holes or Bevels is no problem.

Good Bolt Hole Process

Instantaneously changes speeds and uses sophisticated software algorithms to produce straight through holes.

Automatic Feeding Roller Bed

Techinical parameters

|

Model |

RT400 |

|

Max Cutting Length |

6m / 9m / 12 m |

|

Min Cutting Length |

0.5 m |

|

Max Cutting Diamter |

430mm |

|

Min Cutting Diameter |

30mm |

|

Reposition precision |

0.02mm |

|

Processing precision |

0.1mm |

|

Maximum cutting speed |

12000mm/min |

|

Torch Height control mode |

Automatic |

|

Control system |

EOE-HZH |

|

Electrical Supplier |

380V 50HZ / 3 Phase |

Video

Product detail pictures:

Related Product Guide:

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for Factory Free sample Steel Channels Cutting Machine - Robotic CNC plasma pipe profile cutting machine for square tube – Knoppo, The product will supply to all over the world, such as: Curacao, Lithuania, Benin, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.