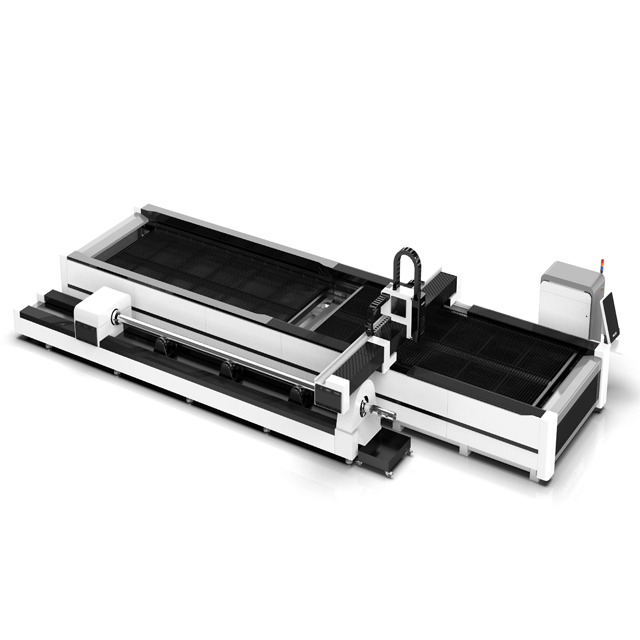

Main Features of KF-T Series dual used fiber laser cutter:

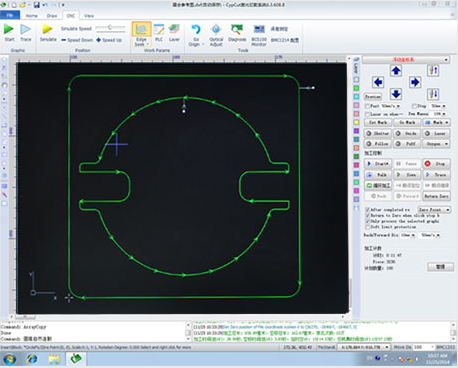

1. BETTER CUTTING QUALITY

Laser has a narrower kerf, meaning less material is wasted. More than this, laser cutting requires less manpower and even no secondary processing for most parts.

2.HIGHER CUTTING PRECISION

Laser cutting, 0.14mm; Plasma cutting, 0.4mm And at the vertical cross, laser cutting has a smaller bevel angle than plasma cutting.

3. LOWER CUTTING COSTS

Getting rid of secondary finishing, with smoother cutting surface, less dross, and smaller deformation.

4. FASTER CUTTING SPEED

Laser cutting speed can reach up to three times faster than plasma cutting.

5. ENVIRONMENT-FRIENDLY PROCESSING

Fiber laser cutting machine is cleaner and more environment-friendly than the smoky and noisy plasma cutting.

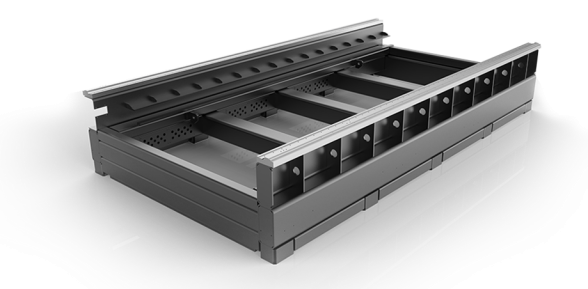

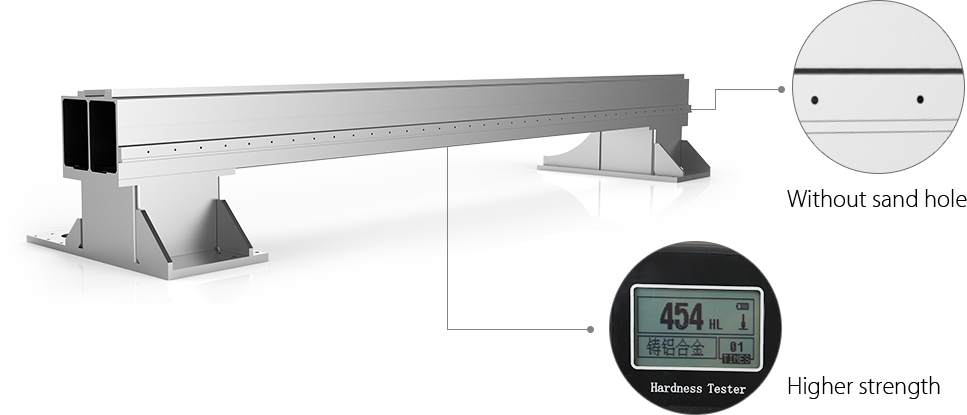

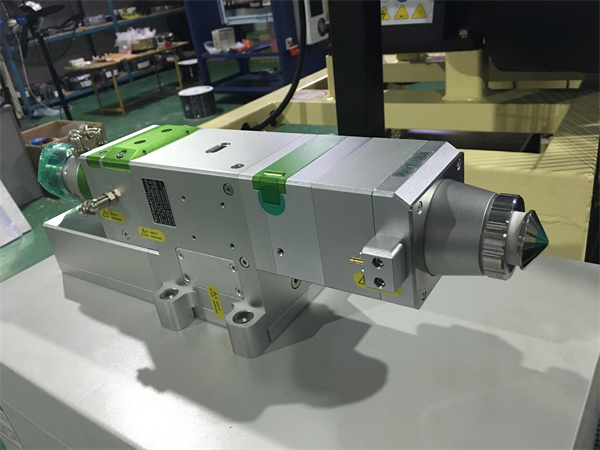

Configuration :

Techinical Parameters

|

Model |

KF-TSeries |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Tube Cutting Length |

3m / 6m |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W /6000W /8000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting Parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0--10 |

15--26 |

24--32 |

30--40 |

33--43 |

|

2 |

4.0--6.5 |

4.5--6.5 |

4.7--6.5 |

4.8--7.5 |

15--25 |

|

|

3 |

2.4--3.0 |

2.6--4.0 |

3.0--4.8 |

3.3--5.0 |

7.0--12 |

|

|

4 |

2.0--2.4 |

2.5--3.0 |

2.8--3.5 |

3.0--4.2 |

3.0--4.0 |

|

|

5 |

1.5--2.0 |

2.0--2.5 |

2.2--3.0 |

2.6--3.5 |

2.7--3.6 |

|

|

6 |

1.4--1.6 |

1.6--2.2 |

1.8--2.6 |

2.3--3.2 |

2.5--3.4 |

|

|

8 |

0.8--1.2 |

1.0--1.4 |

1.2--1.8 |

1.8--2.6 |

2.0--3.0 |

|

|

10 |

0.6--1.0 |

0.8--1.1 |

1.1--1.3 |

1.2--2.0 |

1.5--2.4 |

|

|

12 |

0.5--0.8 |

0.7--1.0 |

0.9--1.2 |

1.0--1.6 |

1.2--1.8 |

|

|

14 |

0.5--0.7 |

0.8--1.0 |

0.9--1.4 |

0.9--1.2 |

||

|

16 |

0.6-0.8 |

0.7--1.0 |

0.8--1.0 |

|||

|

18 |

0.5--0.7 |

0.6--0.8 |

0.6--0.9 |

|||

|

20 |

0.5--0.8 |

0.5--0.8 |

||||

|

22 |

0.3--0.7 |

0.4--0.8 |

||||

|

Stainless steel |

1 |

18--25 |

20--27 |

24--50 |

30--35 |

32--45 |

|

2 |

5--7.5 |

8.0--12 |

9.0--15 |

13--21 |

16--28 |

|

|

3 |

1.8--2.5 |

3.0--5.0 |

4.8--7.5 |

6.0--10 |

7.0--15 |

|

|

4 |

1.2--1.3 |

1.5--2.4 |

3.2--4.5 |

4.0--6.0 |

5.0--8.0 |

|

|

5 |

0.6--0.7 |

0.7--1.3 |

2.0-2.8 |

3.0--5.0 |

3.5--5.0 |

|

|

6 |

0.7--1.0 |

1.2-2.0 |

2.0--4.0 |

2.5--4.5 |

||

|

8 |

0.7-1.0 |

1.5--2.0 |

1.2--2.0 |

|||

|

10 |

0.6--0.8 |

0.8--1.2 |

||||

|

12 |

0.4--0.6 |

0.5--0.8 |

||||

|

14 |

0.4--0.6 |

|||||

|

Aluminum |

1 |

6.0--10 |

10--20 |

20--30 |

25--38 |

35--45 |

|

2 |

2.8--3.6 |

5.0--7.0 |

10--15 |

10--18 |

13--24 |

|

|

3 |

0.7--1.5 |

2.0--4.0 |

5.0--7.0 |

6.5--8.0 |

7.0--13 |

|

|

4 |

1.0--1.5 |

3.5--5.0 |

3.5--5.0 |

4.0--5.5 |

||

|

5 |

0.7--1.0 |

1.8--2.5 |

2.5--3.5 |

3.0--4.5 |

||

|

6 |

1.0--1.5 |

1.5--2.5 |

2.0--3.5 |

|||

|

8 |

0.6--0.8 |

0.7--1.0 |

0.9--1.6 |

|||

|

10 |

0.4--0.7 |

0.6--1.2 |

||||

|

12 |

0.3-0.45 |

0.4--0.6 |

||||

|

16 |

0.3--0.4 |

|||||

|

Brass |

1 |

6.0--10 |

8.0--13 |

12--18 |

20--35 |

25--35 |

|

2 |

2.8--3.6 |

3.0--4.5 |

6.0--8.5 |

6.0--10 |

8.0--12 |

|

|

3 |

0.5--1.0 |

1.5--2.5 |

2.5--4.0 |

4.0--6.0 |

5.0--8.0 |

|

|

4 |

1.0--1.6 |

1.5--2.0 |

3.0-5.0 |

3.2--5.5 |

||

|

5 |

0.5--0.7 |

0.9--1.2 |

1.5--2.0 |

2.0--3.0 |

||

|

6 |

0.4--0.9 |

1.0--1.8 |

1.4--2.0 |

|||

|

8 |

0.5--0.7 |

0.7--1.2 |

||||

|

10 |

0.2--0.5 |

|||||

video

-

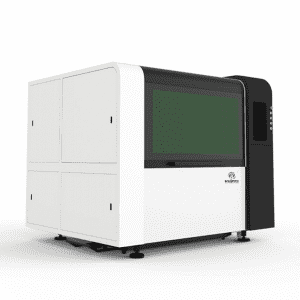

Open Type Metal Sheet Fiber Laser Cutting Machine

-

Full Closed Fiber Laser Cutting Machine For Sta...

-

G Series Sheet Metal CNC Leveling Straightening...

-

1000W 1500W 2000W Small Sheet Metal Fiber Laser...

-

KF3015P Full Covered Single Table Fiber Laser C...

-

4KW 6KW 8KW Steel CNC Fiber Laser Cutting Machi...