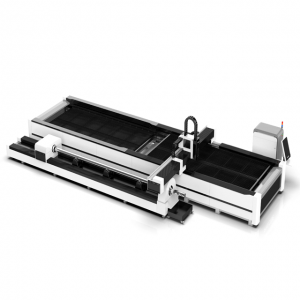

We know that we only thrive if we can easily guarantee our combined price competiveness and excellent advantageous at the same time for Bottom price China Metal Sheet and Pipe Laser Cutting Machine Dual Use, The many thoughts and suggestions is going to be drastically appreciated! The great cooperation could boost each of us into better development!

We know that we only thrive if we can easily guarantee our combined price competiveness and excellent advantageous at the same time for china laser cutting machine, Laser, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is “to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate”.

Application

Applicable Materials Of CNC Fiber Laser Cutting Machine

CNC fiber laser cutting machine can cut thick stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheet, metal plate.

Applicable Industries Of CNC Fiber Laser Cutting Machine

CNC fiber laser cutting machine is used for industry of machinery parts, electrics, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts, metal jewelry and other metal cutting fields.

Sample

Configuration

* Japan SMC Electric Proportional Valve.

*Positioning and re-positioning accuracy is 0.02mm.

* IPG , Raycus or Max laser source in 4KW, 6KW, 8KW, 10KW, 12KW, 15KW, 20KW, 30KW – Lifespan 100,000 hours.

* Precision German PRECITEC auto focus laser head.

* Ball screw drive guide rail system.

* German Rexroth Motor Driver.

*German Rexroth guide rails.

* German Schneider Electronics Parts.

* German BECKOFF software including nesting capability – stable and efficient productivity.

* Water chiller and extraction system included.

Techinical parameters

|

Model |

KP6020 |

|

Wavelength |

1070nm |

|

Cutting Area |

3000*1500mm, 4000*2000mm, 6000*2000mm, 6000*2500mm. |

|

Laser Power |

4KW, 6KW, 8KW, 10KW, 12KW, 15KW, 20KW |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting parameters

|

4000W |

6000W |

8000W |

12000W |

15000W |

||

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8–10 |

8–10 |

8–10 |

9–11 |

9–11 |

|

2 |

5–7.5 |

5–7.5 |

5–7.5 |

5–7.5 |

5–7.5 |

|

|

3 |

3.5–5.0 |

3.5–5 |

3.5–5 |

3.5–5.5 |

3.5–5.5 |

|

|

4 |

3.0–4.0 |

3.0–4.5 |

3.0–4.5 |

3.5–5 |

3.5–5 |

|

|

5 |

2.7–3.6 |

3.0–4.2 |

3.0–4.2 |

3.3–4.8 |

3.3–4.8 |

|

|

6 |

2.5–3.4 |

2.5–3.5 |

2.6–3.7 |

3.0–4.2 |

3.0–4.2 |

|

|

8 |

2.0–3.0 |

2.2–3.2 |

2.3–3.5 |

2.5–3.5 |

2.5–3.5 |

|

|

10 |

1.5–2.4 |

1.8–2.5 |

2–2.5 |

2.2–2.7 |

2.2–2.7 |

|

|

12 |

1.2–1.8 |

1.2–2.0 |

1.2–2.1 |

1.2–2.1 |

1.2–2.1 |

|

|

14 |

0.9–1.2 |

1.2–1.8 |

1.2–1.9 |

1.7–1.9 |

1.5–1.9 |

|

|

16 |

0.8–1.0 |

0.8–1.3 |

0.8–1.5 |

1.2–1.7 |

1.2–1.7 |

|

|

18 |

0.6–0.9 |

0.6–0.9 |

0.8–1.5 |

1.0–1.8 |

1.2–1.5 |

|

|

20 |

0.5–0.8 |

0.5–0.8 |

0.6–1.3 |

0.6–1.5 |

1.2–1.5 |

|

|

22 |

0.4–0.8 |

0.4–0.8 |

0.5–0.8 |

0.5–1.5 |

1.0–1.5 |

|

|

25 |

|

0.3–0.55 |

0.3–0.7 |

0.5–1.1 |

0.8–1.5 |

|

|

30 |

|

|

0.2–0.7 |

0.3–0.9 |

0.6–1.0 |

|

|

35 |

|

|

|

0.3–0.5 |

0.4–0.6 |

|

|

40 |

|

|

|

0.2–0.4 |

0.3–0.5 |

|

|

45 |

|

|

|

|

0.2–0.5 |

|

|

50 |

|

|

|

|

0.1–0.5 |

|

|

Stainless steel |

1 |

32–45 |

42–52 |

50–65 |

70–85 |

72–100 |

|

2 |

16–28 |

20–33 |

30–40 |

40–66 |

45–70 |

|

|

3 |

7.0–15 |

15–22 |

18–27 |

35–45 |

38–50 |

|

|

4 |

5.0–8.0 |

10–15 |

12–16 |

20–32 |

25–35 |

|

|

5 |

3.5–5.0 |

8.0–12 |

10–15 |

18–25 |

20–30 |

|

|

6 |

2.5–4.5 |

4.8–8.0 |

6.0–10.0 |

12–15 |

15.0–25.0 |

|

|

8 |

1.2–2.0 |

3.0–4.0 |

3.5–5.0 |

8–12 |

8.0–12.0 |

|

|

10 |

0.8–1.2 |

1.6–2.5 |

2.0–2.7 |

6.0–8.0 |

6.0–10.0 |

|

|

12 |

0.5–0.8 |

0.8–1.5 |

1.2–2.0 |

4.0–5.5 |

4.0–6.0 |

|

|

14 |

0.4–0.6 |

0.6–0.8 |

1.2–1.8 |

3.0–5.0 |

3.5–6.0 |

|

|

16 |

|

0.5–0.8 |

1.0–1.6 |

2.2–2.8 |

2.5–3.0 |

|

|

18 |

|

0.4–0.6 |

0.8–1.2 |

1.2–2.0 |

1.2–2.2 |

|

|

20 |

|

0.3–0.5 |

0.4–0.7 |

1.0–1.6 |

1.3–1.8 |

|

|

25 |

|

0.2–0.4 |

0.3–0.5 |

0.5–0.8 |

0.6–1.2 |

|

|

30 |

|

|

0.2–0.4 |

0.3–0.6 |

0.5–1.0 |

|

|

35 |

|

|

|

0.3–0.5 |

0.4–0.8 |

|

|

40 |

|

|

|

0.3–0.5 |

0.3–0.6 |

|

|

45 |

|

|

|

0.2–0.4 |

0.2–0.5 |

|

|

50 |

|

|

|

0.1–0.2 |

0.1–0.5 |

|

|

60 |

|

|

|

|

0.1-0.2 |

|

|

70 |

|

|

|

|

0.05–0.1 |

|

|

Aluminum |

1 |

35–45 |

42–55 |

48–65 |

60–85 |

70–100 |

|

2 |

13–24 |

20–40 |

25–48 |

38–50 |

40–55 |

|

|

3 |

7.0–13 |

15–25 |

20–33 |

30–40 |

35–45 |

|

|

4 |

4.0–5.5 |

9.5–12 |

13–18 |

20–30 |

30–40 |

|

|

5 |

3.0–4.5 |

5.0–8.0 |

9.0–12 |

15–25 |

20–30 |

|

|

6 |

2.0–3.5 |

3.8–5.0 |

4.5–8.0 |

10–15 |

15–24 |

|

|

8 |

0.9–1.6 |

2.0–2.5 |

4.0–5.5 |

7.0–12 |

8.0–12.0 |

|

|

10 |

0.6–1.2 |

1.0–1.5 |

2.2–3.0 |

4.5–8.0 |

6.0–10.0 |

|

|

12 |

0.4–0.6 |

0.8–1.0 |

1.5–1.8 |

4.0–5.0 |

4.0–6.0 |

|

|

16 |

0.3–0.4 |

0.5–0.8 |

1.0–1.6 |

1.5–2.5 |

2.0–3.0 |

|

|

20 |

|

0.5–0.7 |

0.7–1.0 |

0.9–1.5 |

1.3–1.8 |

|

|

25 |

|

0.3–0.5 |

0.4–0.7 |

0.6–0.9 |

0.6–1.2 |

|

|

30 |

|

|

0.3–0.6 |

0.3–0.8 |

0.5–1.0 |

|

|

35 |

|

|

|

0.3–0.6 |

0.3–0.8 |

|

|

40 |

|

|

|

0.2–0.4 |

0.2–0.5 |

|

|

50 |

|

|

|

0.1–0.2 |

0.3–0.7 |

|

|

60 |

|

|

|

|

0.2–0.5 |

|

|

Brass |

1 |

25–35 |

35–45 |

40–55 |

55–65 |

75–85 |

|

2 |

8.0–12 |

20–30 |

28–40 |

38–50 |

40–55 |

|

|

3 |

5.0–8.0 |

12–18 |

20–30 |

20–30 |

32–50 |

|

|

4 |

3.2–5.5 |

5.0–8.0 |

10–15 |

15–20 |

27–35 |

|

|

5 |

2.0–3.0 |

4.5–6.0 |

6.0–9.0 |

10–15 |

18–26 |

|

|

6 |

1.4–2.0 |

3.0–4.5 |

4.5–6.5 |

6.0–8.0 |

10–18 |

|

|

8 |

0.7–1.2 |

1.6–2.2 |

2.4–4.0 |

5.0–7.0 |

8.0–10.0 |

|

|

10 |

0.2–0.5 |

0.8–1.2 |

1.5–2.2 |

4.5–6.5 |

5.0–7.0 |

|

|

12 |

|

0.3–0.5 |

0.8–1.2 |

2.4–4.0 |

2.8–4.2 |

|

|

14 |

|

0.3–0.4 |

0.4–0.6 |

0.8–1.5 |

1.0–1.8 |

|

|

16 |

|

|

0.3–0.5 |

0.6–1.2 |

0.8–1.5 |

|

|

18 |

|

|

|

0.4–0.6 |

0.6–0.8 |

|

|

20 |

|

|

|

0.3–0.5 |

0.4–0.6 |

|

|

25 |

|

|

|

|

0.3–0.5 |

|

Video

We know that we only thrive if we can easily guarantee our combined price competiveness and excellent advantageous at the same time for Bottom price China Metal Sheet and Pipe Laser Cutting Machine Dual Use, The many thoughts and suggestions is going to be drastically appreciated! The great cooperation could boost each of us into better development!

Bottom price China Laser Cutting Machine, Laser, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is “to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate”.

-

New Fashion Design for China 2000W Fiber Laser ...

-

Factory Selling China 2021 Lxshow High Quality ...

-

China OEM China Cheap High Quality CNC Tube and...

-

China New Product China Fiber Laser Cut Tube/Pi...

-

Fixed Competitive Price China Automatic Steel H...

-

High Quality for China H Beam Steel Coping Robo...