Features

UV laser marking machine uses a 355 nm wavelength UV laser with a "cold marking" method. The laser beam diameter is only 20 μm after focusing. The UV laser's pulse energy comes in contact with the material in the microsecond. There is no significant thermal influence next to the slit, so no heat damages the electronic component.

- With cold laser processing and a small heat-affected zone, it can achieve high-quality processing

- Wide applicable materials range can compensate for the shortage of infrared laser processing ability

- With good beam quality and a small focusing spot, it can achieve superfine marking

- High marking speed, high efficiency, and high precision

- No consumables, low cost and low maintenance fee

- The overall machine has stable performance, supporting the long-term operation

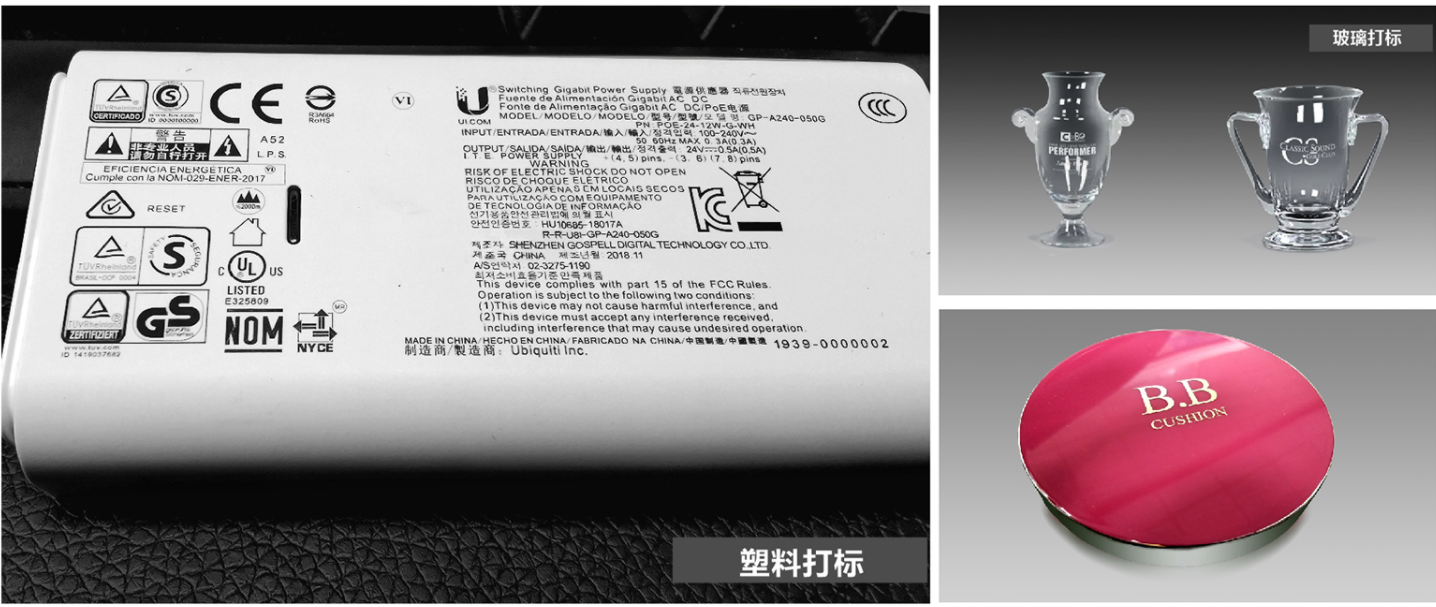

UV laser marking machine is suitable for processing more extensive materials, such as plastics, including PP (polypropylene), PC (polycarbonate), PE (polyethylene), ABS, PA, PMMA, silicon, glass and ceramics etc.

Sample

Techinical Parameters

| Laser Type | UV Laser |

| Wavelength | 355nm |

| Min Beam Diameter | < 10 µm |

| Beam Quality M2 | < 1.2 |

| Pulse Frequency | 10 - 200 kHz |

| Laser Power | 3W 5W 10W |

| Repetition Accuracy | 3 μm |

| Cooling System | Water-cooled |

| Marking Field Size | 3.93" x 3.93 (100mm x 100mm) |

| Operation System | WINDOWS 10 |

| Laser Safety Level | Class I |

| Electrical Connection | 110 - 230 V (± 10%) 15 A, 50/60 Hz |

| Power Consumed | ≤1500W |

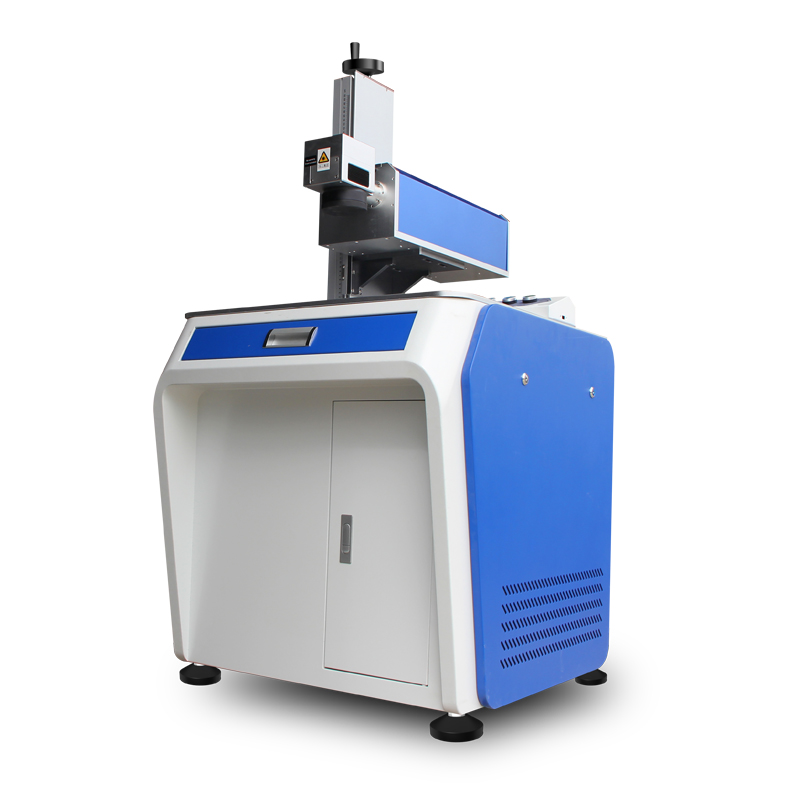

| Dimensions | 31.96" x 33.97" x 67.99" (812mm x 863mm x 1727mm) |

| Weight (unpacked) | 980 lbs (445kg) |

| Warranty Coverage (Parts & Labor) | 3-year |

| Running Temperature | 15℃-35℃ / 59°-95°F |