2020 Latest Design Pipe And Sheet Laser Cutting Machine - Dual Used Metal Pipe And Plate Fiber Laser Cutter 2000W 3000W 4000W 6000W – Knoppo Detail:

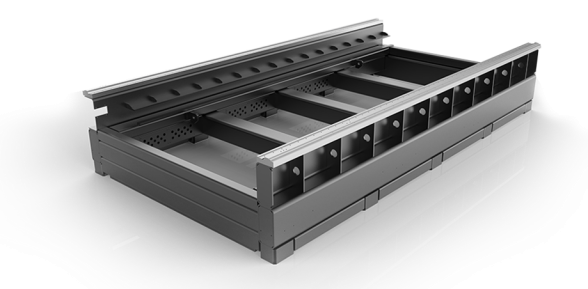

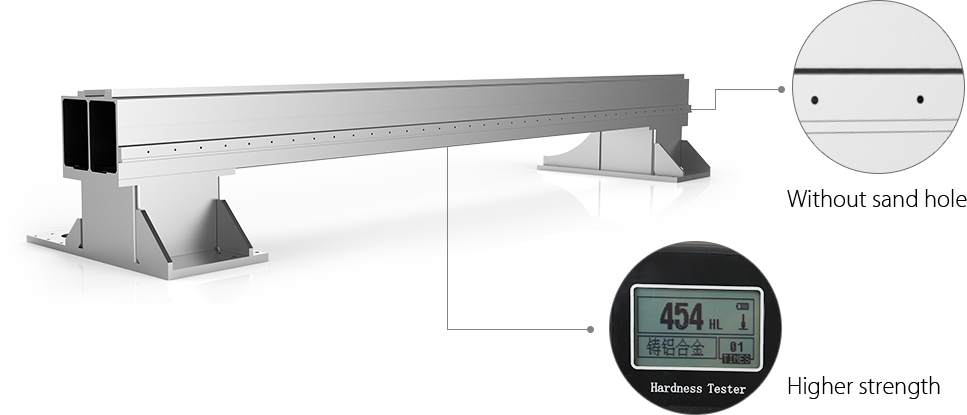

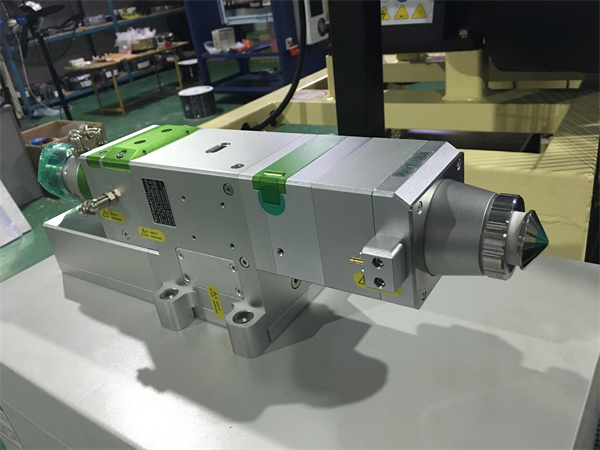

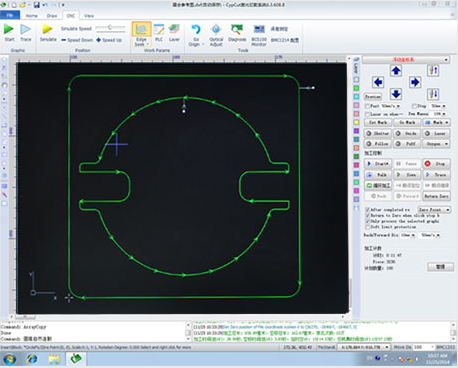

Main Features of KF-T Series dual used fiber laser cutter:

1. BETTER CUTTING QUALITY

Laser has a narrower kerf, meaning less material is wasted. More than this, laser cutting requires less manpower and even no secondary processing for most parts.

2.HIGHER CUTTING PRECISION

Laser cutting, 0.14mm; Plasma cutting, 0.4mm And at the vertical cross, laser cutting has a smaller bevel angle than plasma cutting.

3. LOWER CUTTING COSTS

Getting rid of secondary finishing, with smoother cutting surface, less dross, and smaller deformation.

4. FASTER CUTTING SPEED

Laser cutting speed can reach up to three times faster than plasma cutting.

5. ENVIRONMENT-FRIENDLY PROCESSING

Fiber laser cutting machine is cleaner and more environment-friendly than the smoky and noisy plasma cutting.

Configuration :

Techinical Parameters

|

Model |

KF-TSeries |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Tube Cutting Length |

3m / 6m |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W /6000W /8000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting Parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

||

|

16 |

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|||

|

18 |

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|||

|

20 |

0.5–0.8 |

0.5–0.8 |

||||

|

22 |

0.3–0.7 |

0.4–0.8 |

||||

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

||

|

8 |

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|||

|

10 |

0.6–0.8 |

0.8–1.2 |

||||

|

12 |

0.4–0.6 |

0.5–0.8 |

||||

|

14 |

0.4–0.6 |

|||||

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

||

|

5 |

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

||

|

6 |

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|||

|

8 |

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|||

|

10 |

0.4–0.7 |

0.6–1.2 |

||||

|

12 |

0.3-0.45 |

0.4–0.6 |

||||

|

16 |

0.3–0.4 |

|||||

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

||

|

5 |

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

||

|

6 |

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|||

|

8 |

0.5–0.7 |

0.7–1.2 |

||||

|

10 |

0.2–0.5 |

|||||

video

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for 2020 Latest Design Pipe And Sheet Laser Cutting Machine - Dual Used Metal Pipe And Plate Fiber Laser Cutter 2000W 3000W 4000W 6000W – Knoppo, The product will supply to all over the world, such as: New Zealand, Portugal, Hamburg, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

A good manufacturers, we have cooperated twice, good quality and good service attitude.

-

OEM Manufacturer Plywood Laser Cutter - 4KW 6K...

-

factory customized 20kw Fiber Laser Cutting Mac...

-

Hot sale Iron Laser Cutter - Dual Used Metal P...

-

Europe style for Plasma Cutting Machine Metal -...

-

Free sample for Copper Fiber Laser Cutting Mach...

-

Wholesale Price 1500w Laser Welder - 1000W 150...