We strive for excellence, service the customers”, hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for 2019 China New Design China 500W 1000W 2000W Fiber Laser Cutter 1325 1530 Metal Sheet Fiber Laser Cutting Machine, We warmly welcome mates from all walks of life to hunt mutual cooperation and develop a more good and splendid tomorrow.

We strive for excellence, service the customers”, hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for 500w fiber laser cutting machine, China Fiber Laser Cutter for Metal Sheet, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We’ve been looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

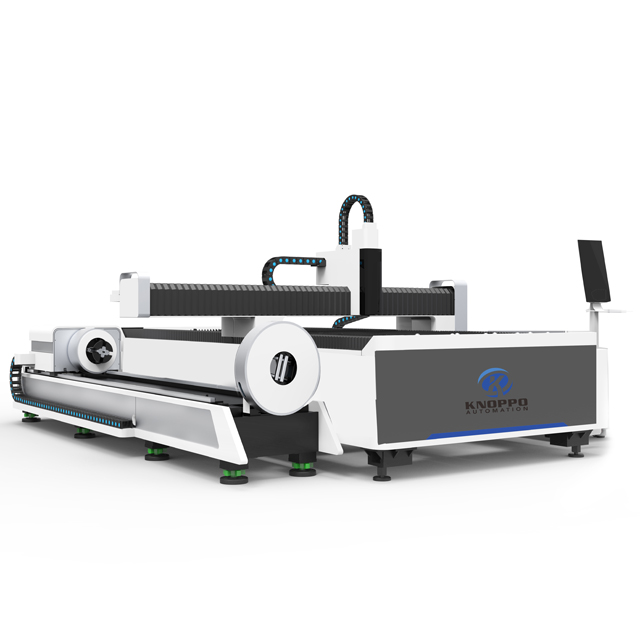

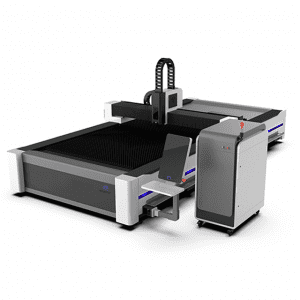

CNC Sheet Metal And Tube Fiber Laser Cutting Machine KF3015T

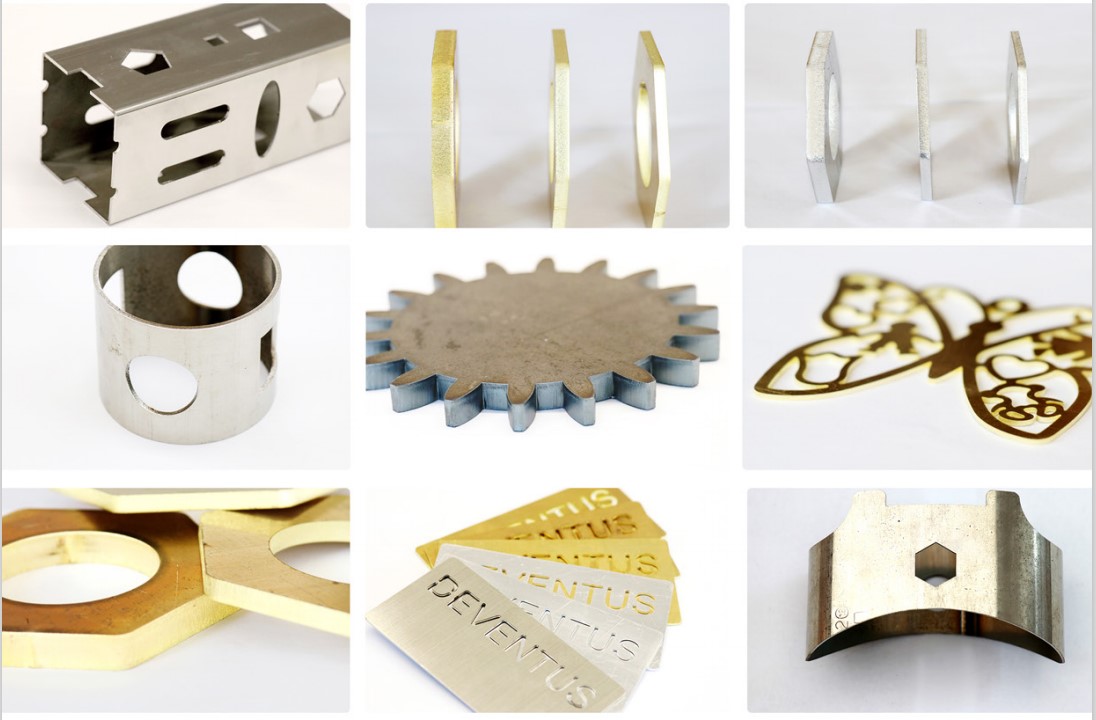

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

Techinical Parameters

|

Model |

KF-TSeries |

|

Sheet Cutting Area |

3000*1500mm / 6000*1500mm / 6000*2000mm/ 6000*2500mm |

|

Tube Cutting Length |

3m / 6m |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W /6000W /8000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

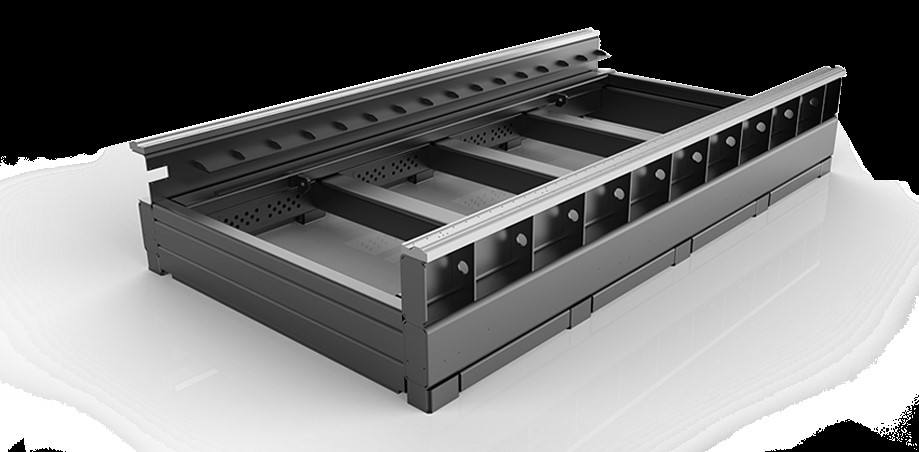

STRONG MACHINE BODY

Using flake graphite cast iron, the lowest tensile strength of which is 200MPa. High carbon

content, high compressive strength and high hardness. Strong shock absorption and wear

resistance. Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using,

so the machine accuracy could maintain fora long time, and no deformation in a life cycle.

SWITZERLAND RAYTOOLS LASER HEAD

AUTO-FOCUS

Applicable to various focal lengths, which are controlled by machine tool control system. Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal.

Free

Free your hands. Focal length is controlled by operating system. We don’t need to do manual regulation,which effectively avoids errors or faults caused by manual operation.

Fast

Adopt Switzerland Lightning technology, perforation time is short, 90% of perforation time is saved; Switzerland Lightning combined with Raytools improved new process so that the perforation is not affected by the material quality and achieve perfect cutting with the best cutting section; saving cutting gas and electricity, saving cost.

When replacing different materials or different thicknesses sheet, manual focus laser head needs to adjust focal length manually,very inefficient; auto focus laser head can read system storage parameters automatically, very efficient.

Accuracy

Increasing perforation focus length, separately setting perforation focal length and cutting focal length,enhance cutting accuracy.

Durable

Built-in double water-cooling structures can ensure constant temperature of collimating and focusing components,avoid lenses overheating and extend service life of lenses; Increasing collimation protective lens and focus protective lens, carefully protect key components.

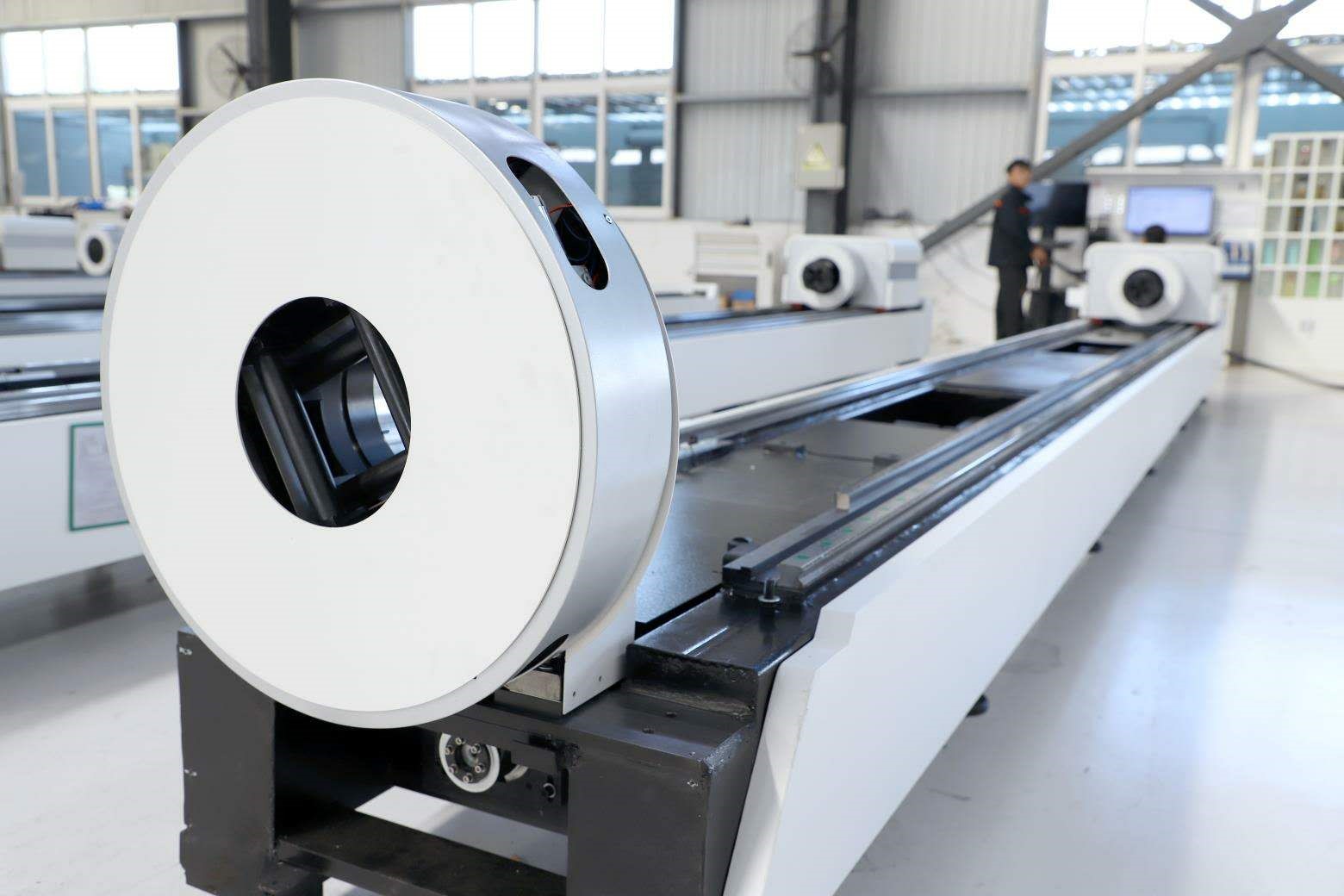

SELF-CENTERING CHUCK

Automatic electric chuck, claw DC motor drive, clamping motor current is sensitive, adjustable and stable, clamping range is wider and clamping force is larger. Non – destructive pipe clamping, fast automatic centering and clamping pipe, performance is more stable. The chuck size is smaller, rotation inertia is low, and dynamic performance is strong. Self-centering electric chuck, gear transmission mode, higher transmission efficiency, long working life and high work reliability.

FUNCTIONS OF KF3015T MODEL

Auxiliary feeding mechanism

The promotion and demotion of subsidiary roller table reduces friction force between parts and working table, making loading and unloading more convenient.

Intelligent travel protection

Automatically monitor operation range of crossbeam and cutting parts, keeping operation within machining range. Double guarantees of fixed limitation greatly improve equipment and personal safety, minimizing the using risks.

Automatic lubrication system

Automatic lubrication system provides timing and ration lubricating oil for equipment to ensure its normal and high speed operation, and owns functions of abnormal alarm and liquid level alarm. The system greatly enhances cutting accuracy and effectively extends service life of transmission mechanism!

WIFI remote intelligent assistance

Global real-time feedback ; Providing real-time fault analysis and troubleshooting.

A new generation of safety following module

Laser head keeping distance with work piece in cutting process can reduce collision risks. It will stop cutting when colliding plate. The safety following module reduces accident rate and improves cutting performance.

Intelligent alarm system

The system will start full abnormal alarm and push it to the interface through control center when equipment is abnormal.

Finding equipment abnormal in advance and reducing hidden dangers can multiply improve the equipment troubleshooting efficiency.

Auxiliary gas low pressure alarm function.

Providing real-time pressure detection, pushing abnormal information when pressure value is lower than optimal cutting effect and precision. Ensure the cutting performance, accuracy and timeliness of gas replacemet.

Cutting Parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

|

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

|

|

16 |

|

|

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|

|

18 |

|

|

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|

|

20 |

|

|

|

0.5–0.8 |

0.5–0.8 |

|

|

22 |

|

|

|

0.3–0.7 |

0.4–0.8 |

|

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

|

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

|

|

8 |

|

|

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|

|

10 |

|

|

|

0.6–0.8 |

0.8–1.2 |

|

|

12 |

|

|

|

0.4–0.6 |

0.5–0.8 |

|

|

14 |

|

|

|

|

0.4–0.6 |

|

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

|

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

|

|

5 |

|

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

|

|

6 |

|

|

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|

|

8 |

|

|

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|

|

10 |

|

|

|

0.4–0.7 |

0.6–1.2 |

|

|

12 |

|

|

|

0.3-0.45 |

0.4–0.6 |

|

|

16 |

|

|

|

|

0.3–0.4 |

|

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

|

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

|

|

5 |

|

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

|

|

6 |

|

|

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|

|

8 |

|

|

|

0.5–0.7 |

0.7–1.2 |

|

|

10 |

|

|

|

|

0.2–0.5 |

|

Video

We strive for excellence, service the customers”, hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for 2019 China New Design China 500W 1000W 2000W Fiber Laser Cutter 1325 1530 Metal Sheet Fiber Laser Cutting Machine, We warmly welcome mates from all walks of life to hunt mutual cooperation and develop a more good and splendid tomorrow.

2019 China New Design China Fiber Laser Cutter for Metal Sheet, 500W Fiber Laser Cutting Machine, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We’ve been looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

-

Quots for China Fiber Laser Cleaning Machine La...

-

Renewable Design for China 1000W/2000W/3000W Fi...

-

Quoted price for China Monthly Deals Customized...

-

New Delivery for China Factory Laser Cutter CNC...

-

Hot sale China 1kw 1.5kw 2kw 3kw 4kw 6kw Fiber ...

-

OEM Supply China Steel Beam Plasma Cutter Porta...